- Home

- Companies

- SA Fire Protection

- Products

- SA-Fire - Carbon Dioxide Systems (CO2)

SA-Fire - Carbon Dioxide Systems (CO2)

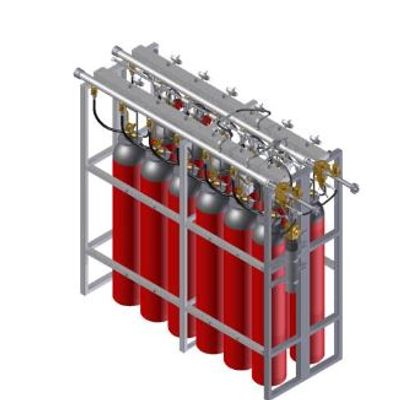

Carbon Dioxide (CO:) is widely used in the fire industry as an extinguishing agent for total flooding and local application fire suppression systems. The SA High Pressure carbon dioxide fire extinguishing system provides protection for a variety of industrial hazards. Each system is manufactured according to client specifications and may assume various configurations depending on the features that are selected Standard systems are made of cylinder assemblies, valves, actuators, a manifold and discharge nozzles. All cylinders are secured to a cylinders` wall or rack self-standing open type, closed cabinet or container. The latter may include also complementary systems and controls such as lights, heaters and HVAC. Each cylinder bank, independently from its configuration, may be provided with components suitable for hazardous areas and/or with SIL 2 or 3 compliant actuators.

The open rack type assembly is a self-standing structure made of galvanized steel. It hosts the system manifold in the middle of the rack using a reinforced channel to hang cylinders by means of their weighting system. The closed cabinet is a fully covered, self-standing structure with one or more doors for system inspections. The cabinet is manufactured using a galvanized steel frame with carbon steel sheets covering the structure. The cabinet may be provided with insulation material on all sides and with additional systems such as heaters and air conditioning.

Actuation Types:

The SA High Pressure carbon dioxide extinguishing system may be selected among two methods of actuation. The first type uses an auxiliary cabinet with one or two nitrogen pilot cylinders. In this case, the nitrogen cylinders may be actuated electrically using a solenoid valve (single or redundant) or manually by means of a manual pull lever. In any case, when actuated the nitrogen is released towards the (CO;) valves resulting in their sequential actuation. In this installation, all the (CO:) cylinders are configured as slaves meanwhile the pilots consist of an external source of nitrogen cylinder(s). The second possible actuation is known as MASTER/SLAVE and consist of connecting the solenoid actuators directly on top of the (CO:) valves. In this case, the pilot cylinder(s) are represented by the same (CO;) cylinders present in the system. Upon actuation, the (C02) is released from the pilot(s) and then diverted to the slave cylinders resulting in a quick and sequential actuation of the whole system.