- Home

- Companies

- Zhengzhou Shuliy Machinery Co., Ltd

- Products

- Shuliy - Model SL - Charcoal ...

Shuliy - Model SL -Charcoal Carbonization Furnace - Biomass Charcoal Making Machine

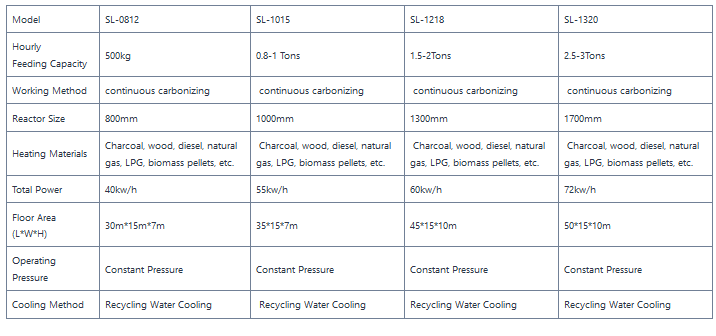

Carbonization furnaces, it has a stronger carbonization function, a wider range of materials that can be carbonized, and continuous production with higher production efficiency. This charcoal carbonization furnace is large-scale carbonization equipment. Compared with other carbonization furnaces, it has a stronger carbonization function, a wider range of materials that can be carbonized, and continuous production with higher production efficiency. This machine has not only a large output that can produce 3 tons/hour, but also a small model of 500kg/h. Biomass charcoal making machine is most commonly used in the production of carbon and rice husk carbon and is often used in hookah carbon production lines and barbecue carbon production. In the past, carbonization furnaces were exported to Germany, Iran, Japan, and Malaysia.

For this carbonization furnace, basically, all products containing carbon can be carbonized, especially some kitchen waste, waste clothes, animal manure, and even river sludge can be carbonized. Specific common materials include straw scraps, rice husks, straw, sawdust, nutshells, bark, bamboo powder, bamboo chips, branches, tree roots, coconut shells, jujube stones, peels, cow bones, cow dung, etc.

Biomass charcoal making machine processing conditions

The humidity is below 25%. If there is too much moisture, it needs to be dried first. The fineness of the material is 20mm. If the material is too large, it needs to be crushed first. The general carbonization time is 18-20 minutes, and a batch can be carbonized in about 20 minutes, and the production efficiency is very high.

Raw Material

Finished Product Biomass charcoal making conditions Charcoal carbonization furnace structure Carbonization Furnace Structure

The basic structure of the machine includes a carbonization furnace, gasification furnace, soot processor, combustible gas purifier, and an intelligent numerical control panel added to its console.

- Carbonization furnace charging

- Carbonization furnace drying

- carbonization furnace

- Carbonization furnace intelligent control panel

Smokeless carbonization design

Adopting a new innovative structure, the combustion exhaust gas can be discharged up to the standard, and the combustion flue gas can be fully utilized to achieve smokeless carbonization during the operation process.

Continuous operation and large-scale production

The continuous carbonization furnace overcomes the disadvantages of the traditional batch carbonization furnace, and through innovation, it can carry out efficient continuous production. Taida’s new continuous carbonization furnace is based on the drum carbonization furnace and iteratively upgrades to help users achieve large-scale production.

Priority material and life guarantee

The combustible combustion system adopts high-frequency welding, and the heating shell is lined with high-temperature refractory fiber, which has a long service life and burning wearing parts, which makes users more worry-free.

Low energy consumption and green production

The production process of carbon/gas/oil co-production is realized, and the traditional defects of high energy consumption/high pollution/low efficiency are solved. In the carbonization process, tar/wood vinegar and combustible gas are all recovered and reused.