- Home

- Companies

- CHOREN Industrietechnik GmbH

- Products

- CCG - Choren Coal Gasification Process

CCG - Choren Coal Gasification Process

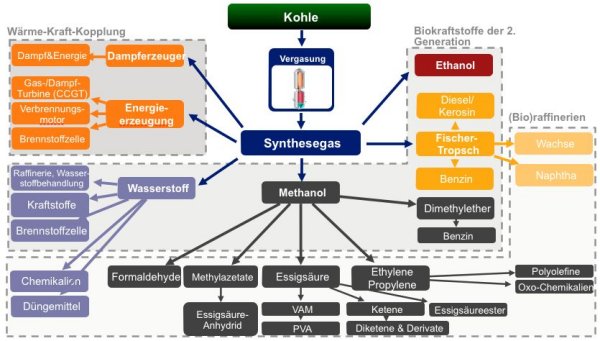

The CCG technology is based on a long-standing, proven process of coal gasification for the generation of an ultra-pure, high-energy synthesis gas. This is the base material for the manufacture of classical synthesis gas products, such as methanol and ammonia, and is used for the manufacture of fuels and a great number of chemical base materials, or can be used for electric power and heat generation.

As a result of the application of the innovative burner concept for the dry coal-dust gasification, as well as the subsequent water-quench, the following advantages result for the process:

- High quality of the synthesis gas: No aromatics, tars, phenols and condensates

- High raw material variability: Hard coal, lignite, petroleum coke, mixtures of waste and/or biomass

- The employment of inferior coal qualities with high ash content is possible

- Low capital expenditure due to compact design and optimized water-quenching

- Low operating costs

- High flexibility through fast startup and shutdown

- High level of plant availability through simple and rugged design

The high-energy and high-purity synthesis gas made of biomass, coal or other carbonaceous materials can be used for the production of classical synthesis gas products, to generate electricity and for the production of fuels.

Stage One

The pulverized coal is pneumatically brought into a pressurized dosing and feed system, fluidized therein and conveyed as

pulverized coal - carrier gas - dispersion to the gasification reactor.

Advantages of this pneumatic dense flow conveying are high constancy and good controllability of the dust stream and an almost wearless conveying even with abrasive dusts. Compared with a feed as a pulverized coal - water - suspension, a higher gasification efficiency is achieved at a low oxygen consumption because no additional water must be evaporated from the suspension.

Stage Two

Gasifying the pulverized coal occurs by partial oxidation in the air current with the supply of oxygen and water vapor at elevated pressure. The carbon combines with the oxygen to form carbon monoxide. The CCG® - gasifier has an optimized dust burner system regarding to the burnout. At the same time, the investment and operating costs were compared with those of known solutions significantly reduced.

The ruling temperatures in the oxidizing flame zone (> 2000 ° C) above the melting point of the fuel ash guarantee a fast and almost complete fuel conversion. All hydrocarbons are completely decomposed.

The gasification chamber is covered by a cooling screen. The dross solidifies inside on the cooling screen and forms a protective film against thermal overcharge of the reactor. As a thermotechnical favorable solution the raw gas escapes together with the molten dross from the molten slag enters together from the reaction chamber, whereby the of risk disturbance in the dross discharge is considerably reduced.

Stage Three

The separation of the raw gas from the liquid dross is carried out during the subsequent quenching. The granulated dross can be used as building material.

The high-temperature gasification in entrained flow under pressure produces a very pure and energy-rich synthesis gas having the following properties:

- CO + H2> 90 vol%

- tarless

- free of condensate

- free from aromatic compounds

Process Parameters

- High-temperature gasification (1400 - 1700 ° C)

- Services of synthesis gas production: gasifier power 200 to 800 MW

- Gasifying instrumentss: oxygen, or oxygen mixed with steam and / or CO2

- Fuels can be used with an ash content up to 35%

- Ash melting point

- Operating pressure 40 bar in the carburetor

Further Advantageous Features the CCG Process

- Carbon conversion rate> 99%

- High cold gas efficiency

- No restrictions on the sulfur content

- High burner durability (1 inspection / year)

- Cooling screen instead of refractory lining, enabling rapid approach and retraction

- High cooling screen durability up to 20 years

- Optimized Wasserquenchung

- High gasifier durability by dross protective layer in the gasifier

- Lower oxygen consumption of the dust gasification compared to the gasification of slurry

Ash-containing solid or liquid fuels, gases as a fuel additive

Demands on the Ingredient

- Minimum content of ash

- Suitable ash composition (melting behavior, viscosity)

Addition in the Solid Fuel

- Ggrindability

- Drying to the removal of surface moisture (coal <2%, lignite <8 .12%)

Coal

Almost all types of coal can be used, from lignite to anthracite coal. Also the use of ash-rich coal is possible. The method is also suitable for salt coal, which is rarely used so far.

Petroleum Coke

This is easily used in a mixture with coal or alone after addition of a minimum amount of ash.

Torrefied Biomass

By thermal treatment of biomass under exclusion of air at 250 to 300 ° C (pyrolysis) their fuel properties improve significantly. The torrefied biomass has a porous, carbon-like structure and may be ground as coal and mixed with the main fuel.