General Electric

- Home

- Companies

- General Electric

- Products

- Circulating Fluidized Bed Boilers (CFB)

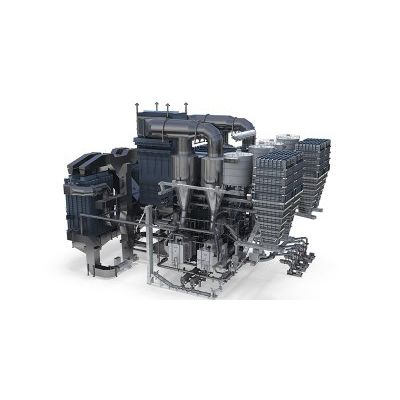

Circulating Fluidized Bed Boilers (CFB)

FromGeneral Electric

Over the past two decades, CFB technology has demonstrated its ability to efficiently utilize a wide variety of fuels while still meeting stringent stack emission limits.

Most popular related searches

circulating fluidized bed boiler

circulating fluidized bed

fluidized bed boiler

fluidized bed

furnace

shale oil

fuel efficiency

Efficient combustion and fuel flexibility

A wide range of fuels can be burned efficiently, including low-grade and difficult-to-burn fuels such as anthracite, lignite, petroleum coke, oil shale, discarded coal, and biomass within a wide range of mixing rates

Low inherent NOx emissions at 50-200 mg/Nm3

Relatively low and uniform furnace temperatures of approximately 850°C to 900°C.

Selective non-catalytic reduction (SNCR) systems can be added, leading to even lower NOx emissions.

Selective non-catalytic reduction (SNCR) systems can be added, leading to even lower NOx emissions.

Low SO2 emissions with 95-98%sulfur removal

Injection of prepared and dried limestone in the furnace.

Dry scrubber NID* achieving 98% sulfur removal while reducing limestone consumption.

Just-In-Time (JIT*) system for limestone drying and crushing available for direct limestone feeding.

Dry scrubber NID* achieving 98% sulfur removal while reducing limestone consumption.

Just-In-Time (JIT*) system for limestone drying and crushing available for direct limestone feeding.

Ultra-supercritical CFB

660 MWe for lignite B, higher for hard coal

- Ultra-supercritical 285 bar, 605°C/623°C (MS/RH)

- More than three points increased net plant

- efficiency relative to subcritical

- 6% reduction of CO2 footprint

- Inherent low NOx emission with our air staging

- Low SO2 emission without backend treatment

- Designed for reliability:

- Well-tested material for pressure parts with many years of onsite experience

- Multiple fuel feeders and ash extraction ports

- Standardized modules that allow changing outputs, fuels, and steam temperatures