- Home

- Companies

- Sitong Boiler

- Products

- Sitong - Model DZL Series - Coal Fired ...

Sitong - Model DZL Series -Coal Fired Stoker Boiler

DZL series coal fired stoker boiler is single drum, the combustion equipment is chain grate stoker. Water wall tubes at left and right sides of furnace are the radiated heating area. the two wings at furnace and screw fire tube in the drum are convection heating area. This coal fired stoker boiler uses the upper drum, water wall tube and head are in symmetrical arrangement mode. The drum is welded assembly by cylinder and front back tube plate. This furnace structure in reasonable arrangement and high efficiency. This stoker boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement. This series coal fired stoker boiler uses the new scientific achievement, such as arch tube plate, screw fire tube to solve the problem of tube plate flaw, water wall tube explosion, low efficiency, insufficient output, poor adaptability of coal, improve the heat transfer.

Introduction

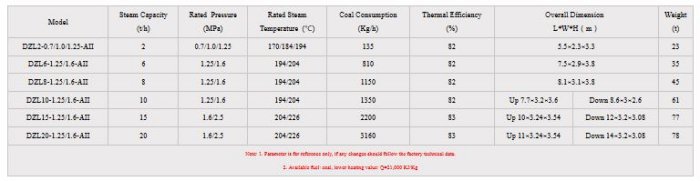

- Steam Capacity 1t/h-30t/h

- Steam Pressure 0.7Mpa-3.8Mpa

- Fuel Coal

- Application textile plant, rice mill, garment factory, utility or power plant, hospital, hotel, food & beverage, diaries, schools, etc.

- Certification ISO,CE,GSG, BV

Customer Inquiry -- Offer Professional Consulting Service -- Place Order -- Customize Boiler Based on Customers’ needs --Production-manufacturing -- Payment -- Impeccable After Sale Service (installation and debugging, periodic maintenance, etc.)

Offered Technical Documentations

- Installment and Operation Instruction

- Quality Certificate

- Inspection Certificate of Boiler quality

- General Drawing of Boiler

- Foundation Drawing

- Boiler Body Drawing

- Boiler Room Design Drawing

- Drawing of Valves, Instruments and Accessories

Sitong boiler is a national approved and designated enterprise, with design and manufacture license permits of Class A boiler and D1, D2 pressure vessel. The company has passed ISO 9001 international quality system certification, and gained the international certificates of CE, SGS, and BV, etc. The boiler products are exported to more than 60 countries. The factory covers an area of 120 thousands㎡, equipped with plenty of international advanced manufacture equipment, such as CNC cutting machine, automatic submerged arc welding machine, X-ray detection machine, etc.

- The small scale stoker could resist the temperature as high as 1200℃, long working life.

- The stoker has a low coal leakage because of the small gap.

- High automatic degree, decrease labor cost.

- Convenient for maintenance, it could be repaired without boiler shut down.

- There is a professional design engineer team, before manufacturing, every boiler design drawing have to be approved by boiler and pressure vessel experts of CSBTS ( State Bureau of Quality Technical Supervision ), and then the boiler could be produced only if qualified.

- To ensure the raw materials quality, all the steel plates are special-used for boiler with the Inspection Certificates. The raw material materials are inspected when entering factory, and only the qualified material could be put in storage and used for production.

- To ensure the welding quality, there a professional welding team, including more than 30 senior welders. The welding materials are stored under constant temperature and humidity, to ensure the welding material quality.

- The welding quality will be further examined during boiler manufacturing, by using x-ray detection, ultrasonic flaw detection, magnetic test, or penetration test, etc.

- To ensure the boiler quality, the leakproofness and strength of pressure parts will be tested. The hydrostatic test is done to make sure there are no water drop or water mist leakage appear on steal wall or welding joint, no water leakage appear at the place of expansion, and no obvious residual deformation and abnormal situation.

- To ensure no problems before boiler delivery, all the raw materials and boilers are supervised and inspected by the experts of Inspection Institution for Boiler and Pressure Vessel. There are international uality certificates of ISO 9001 and CE, we can also offer the inspection report of SGS, BV, etc., Quality Certificates, Energy audit report, and Energy Efficiency Test Report, etc.