Martin GmbH für Umwelt- und Energietechnik

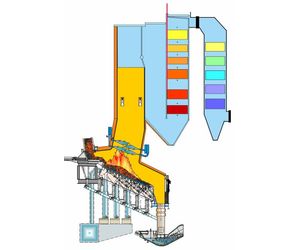

Martin - Combustion System

The combustion system, consisting of the grate system and furnace, forms the technological focal point of waste-to-energy plants. Various combustion concepts are available to achieve the best possible burnout at low flue gas flows and the lowest emission levels in terms of the elements influenced by the combustion process (CO, CxHy, NOx).

Most popular related searches

The concepts differ in particular in terms of the composition of the combustion air supplied:

- Conventional – primary and secondary air is being fed to the combustion process

- Staged combustion – combustion air injection adjusted to the fuel characteristics and increased residence time for reducing emissions

- Flue gas recirculation – most of the secondary air is replaced with dedusted flue gas

- SYNCOM – part of the primary air is enriched with pure oxygen; most of the secondary air is replaced with dedusted flue gas

The grate systems used are the MARTIN reverse-acting grate Vario, the MARTIN reverse-acting grate, the MARTIN horizontal grate and the MARTIN reverse-acting grate SITY 2000.