Torftech Group

- Home

- Companies

- Torftech Group

- Products

- Torftech - Model CBR - Compact Bed ...

Torftech - Model CBR -Compact Bed Reactors (CBR)

FromTorftech Group

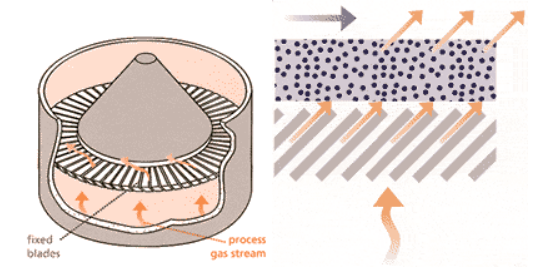

The particles to be processed are held in a shallow bed suspended by jets of the process gas stream that is forced through stationary angled blades at high velocity. The process gas stream impacts on and minimises the insulating microscopic gas layer around each particle. As a result, the heat and mass transfer rate is greater than in other types of reactor which means faster, more effective processing.

Most popular related searches

- Efficient heat mass transfer means faster, more cost effective processing

- Materials do not have to be carefully graded

- The process is capable of being very accurately controlled

- The toroidal bed motion exposes the greatest surface area possible to the gas stream

- Substantial energy savings and easier recycling of the process gas stream as the static pressure loss across the bed is low

- Mass flows of the process gas can be optimised and are not strictly linked to particle size

Full size TORBED CBRs are already operating in a wide variety of industries including:

- Mineral

- Metallurgical

- Chemical

- Food