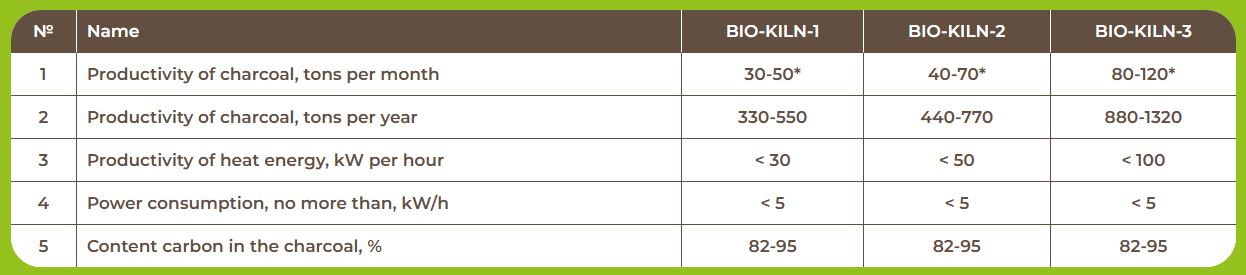

GreenPower BIO-KILN - Continuous Carbonization Furnace

The carbonization furnace BIO-KILN is a patented, environmentally friendly, continuous installation for the thermal processing of plants materials. It is designed specifically for the production of high-quality charcoal or biochar as a raw material for the production of hookah charcoal, BBQ briquettes, activated carbon. The charcoal-burning complex based on the BIO-KILN carbonization furnace allows automating the entire production process of producing charcoal: the processes of loading raw materials and unloading finished charcoal, it also makes it possible to automatically control the content carbon in charcoal, minimize ash content, increase the output of charcoal, eliminate the influence of the human factor and achieve consistently high performance indicators of the furnace.

- Reliability of the furnace. The carbonization device is made 100% from refractory materials.

- The process is 100% environmentally friendly, only water vapor and carbon dioxide are released

- Lack of liquid pyrolysis products, they completely burn out without leaving any traces and generate heat energy

- High efficiency from a compact device

- High productivity: 30-120 t / month, depending on the raw materials parameters and the furnace model (Bio-Kiln 1, 2 or 3)

- The furnace operates 24/7 and does not require technological stops

- The process is 100% automated and eliminates the influence of the human factor

- Modern management and control: LCD display, language bar, memory, cloud service and other modern features

- Production of thermal energy, which can be used for drying of raw materials, drying of charcoal briquettes, or other heating purposes

- Complete lack of energy consumption provides kiln autonomy

- Remote Control

- High yield and quality of charcoal

- Wide range of raw materials

- Content carbon in charcoal from 78% to 95%

- constant quality parameters and output volumes of the product are readily achieved, since charcoal production occurs without human intervention in the technical process, namely in automatic mode

- the minimum ash content in the resulting charcoal is achieved by separating ash in raw materials and finished charcoal, and the possibility of burning coal is also excluded. This factor reduces the amount of ash in the charcoal for hookah or BBQ

- lowest equipment price with high performance

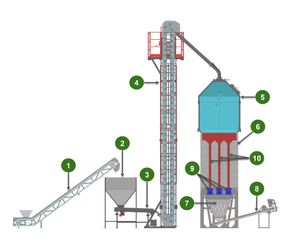

Main elements of the continuous charcoal furnace BIO-KILN

- Belt conveyor of the storage hopper

- Storage hopper

- Vibrating feeder

- Bucket elevator

- Loading hopper

- Pyrolysis chamber

- Unloading hopper with air cooling system

- Screw conveyor

- Unloading devices

- Channels for raw materials

Pre-shredded raw materials are loaded using a conveyor 1 or a bucket loader into the storage hopper 2, from which, using a vibrating feeder 3, the raw material is fed into the bucket elevator 4 for loading into the loading hopper of the furnace 5, from which the raw material, under the action of gravity through the channels for raw materials 10, enters the carbonization chamber 6, where it is converted into charcoal. The finished charcoal through the unloading devices 9 enters the stabilization hopper 7, where it is forcedly cooled, after which the cooled charcoal is unloaded using a screw conveyor 8. Can be unloaded: into metal boxes, trolleys, onto a conveyor or into a hopper, at the request of the Customer, depending on the logistics of the production site.

The flue gases, after the carbonation device, enter the afterburner, where they are completely burned with high temperatures more 1250°C decomposition, ensuring 100% environmental friendliness of the furnace – no harmful emissions into the atmosphere. Exhaust flue gas temperature after the afterburner of the furnace is more than 1000°C, which makes it possible to use them for various thermal processes: preliminary drying of raw materials, heating of premises, charcoal briquette drying, steam production, etc.

The discharged product is then sent to packaging or to the line for the production of briquettes for hookah and barbecue, where it is initially crushed, mixed with water and passed through an extruder to form briquettes of a given shape.

ACS ensures safe and efficient operation of the BIO-KILN. The loading hopper of the furnace 5 is equipped with capacitive sensors that give a signal to turn on and off the vibrating feeder 3 and the bucket elevator 4. This makes it possible to automatically “turn off / turn on” the system for loading raw materials into the loading hopper of the furnace 5 in case of failure of the elements for loading raw materials or for other reasons , ACS switches off devices for unloading finished charcoal 10. BIO-KILN is equipped with thermocouples that automatically control the set quality of charcoal and ensure its unloading into the stabilization hopper 7. As hopper 7 is filled with finished charcoal, special sensors send a signal to the drive auger 8 about the need to unload the cooled charcoal from the hopper.

A visualization of the benefits of hookah charcoal and charcoal briquette for BBQ, obtained using the BIO-KILN, is presented here.

An illustration of the advantages of biochar, obtained using the BIO-KILN, is presented here.