GreenPower Carbon-Flow - Continuous Lump Charcoal Production Furnace

Carbon-Flow system represents the forefront of lump charcoal production eco friendly technology, designed with a focus on efficiency and sustainability. Developed with insights from Perechenskiy LHK in Perechin, Ukraine, this system minimizes human involvement and maximizes the use of internal heat for the pyrolysis process, ensuring a high-output and low-energy operation. The unit is designed for continuous production of high-quality lump charcoal from wood logs and wood waste.

- Wood Storage and Handling: Wood is delivered by motor transport, avoiding dependence on railway logistics. The storage area allows for up to six months of wood stock, facilitated by a specialized manipulator for efficient handling.

- Automated Logging: The system automatically processes logs into chops suitable for drying and pyrolysis, with a focus on reducing waste and optimizing material use.

- Advanced Drying Techniques: Wood is dried using a vertical dryer that utilizes the heat from pyrolysis gases, enhancing energy efficiency and reducing operational costs.

- Efficient Pyrolysis: The heart of the system, our pyrolysis process is facilitated by a vertical retort, which operates with minimal external energy input. The process is finely controlled to optimize the production of high-quality charcoal.

- Gas Treatment and Utilization: All gases and by-products from pyrolysis are fully utilized either for energy production or treated to minimize environmental impact.

- Energy Recovery: Excess heat is captured through a waste-heat boiler, contributing to the system’s energy efficiency and providing steam for operational needs.

- 7. Product Handling and Packaging: Post-pyrolysis, the charcoal is cooled, screened, and packaged with minimal exposure to air to prevent contamination and ensure product quality.

- Capacity: The system supports a production capacity ranging from 300 to 1000 tonnes of charcoal per month, making it suitable for both small and large-scale operations.

- Automation and Control: Equipped with state-of-the-art control systems, Pyro-Carbon-Flow allows for precise monitoring and adjustment of all processes, ensuring optimal performance and product quality.

- Sustainability: By integrating complete gas utilization and energy recovery, the system not only meets but exceeds modern environmental production standards.

The following solutions are used in the unit

- Production process is provided by its own heat due to the complete combustion of the wood pyrolysis products in the large furnace. The resulting flue gases have an enthalpy

- This enthalpy is sufficient to effect preliminary wood drying, to provide pyrolysis process and charcoal tempering process and also to produce heat energy for household and technical needs

- The same solution provides the recycling of liquid phase which is formed during the wood pyrolysis. The liquid phase recycling eliminates a significant environmental problem of getting acid residues in the soil and wastewater

- Increased charcoal yield is achieved by automatic control of wood pyrolysis temperature and by strict control of oxygen content in the coolant and cooling gases

- Disposal of excess heat is provided by the installation of heat-recovery boiler and steam turbine, if generation of electricity is needed and recycling of waste

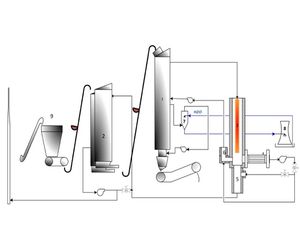

- The charcoal-burning plant includes:

- vertical kiln of shaft type;

- a vertical twin wood dryer;

- recovery-boiler and a furnace for the pyrolysis products burning;

- other equipment is in accordance with agreed specifications.

- Continuous action vertical pyrolysis retort

- Continuous action vertical wood dryer

- Pyrolysis-gas vortex firebox

- Heat utilizer – steam boiler

- Mixing device for preparation of the heat carrier for the wood dryer

- Mixing device for preparation of the heat carrier into the retort

- Cooling system

- Cooling tower

- Intermediate raw material hopper

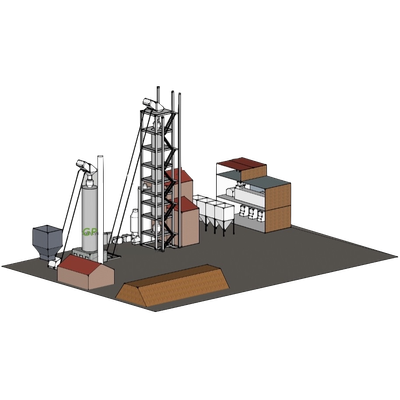

The area of the site for the installation is largely dependent on the choice of equipment, primarily for cutting and packing, as well as on the supply of logs, which depends on the stability of supply.

Below is a variant of the location of the main equipment, excluding the transformer substation, the circulating and fire-fighting water supply system (determined by possible sources of water replenishment), the administrative building, as well as some possible other areas determined by the terms of reference, initial data, local legislative requirements.

Carbon-Flow is designed for efficiency and sustainability, providing a reliable and eco-friendly solution for charcoal production at scale. Whether upgrading from traditional methods or setting up a new production facility, our system delivers unmatched performance and environmental compliance.