Cycle0 - Biogas to Biomethane Upgrading Technologies

FromCycle0

Delivering biomethane from agri-food waste with proprietary biogas upgrading and RNG liquefaction technology. Our small-to-medium-scale biomethane plants use proprietary upgrading and liquefaction technologies to deliver more efficiency than traditional large-scale facilities. Engineered by our Spanish manufacturing subsidiary, FNX, our modular, skid-mounted plants are simple to install in even the most remote sites, allowing agri-food producers to unlock value from waste and contribute to the circular economy.

Most popular related searches

biogas biomethane upgrading

biogas upgrading system

biomethane upgrading

biogas upgrading

biomethane

biomethane plant

biogas

biomethane system

membrane biogas upgrading system

biogas biomethane

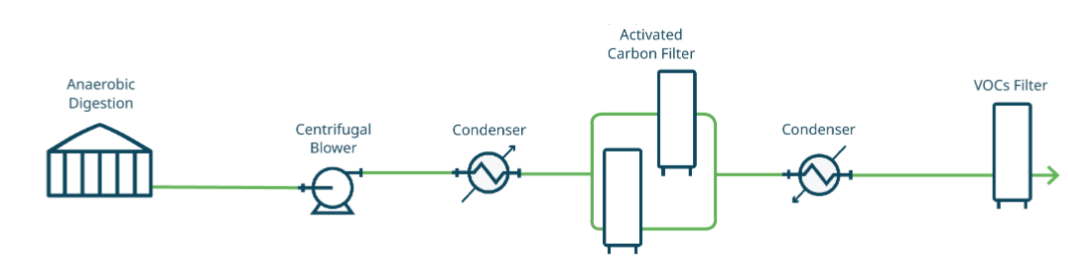

Module 1: Pre-treatment

- Biogas is fed into a pre-treatment container.

- Biogas is cooled to remove excess water.

- H2S is removed using carbon filters.

- Volatile organic compounds are filtered.

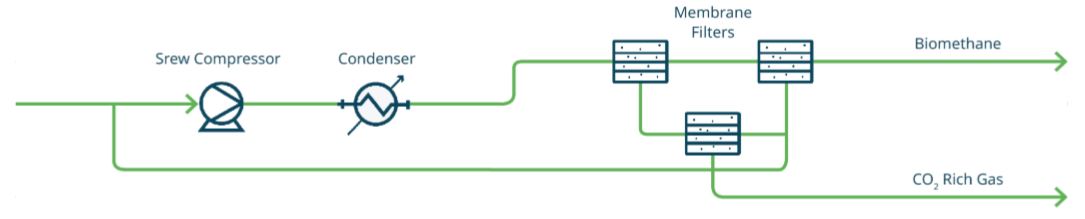

- Pressure is increased via a screw compressor.

- Gas is cooled with a condenser to remove any H2O.

- Methane is separated from CO2 by membrane filters.

- Biomethane is injected into the grid or used for vehicle fuel.*

As an integrated biomethane supplier, we build, own and operate biomethane plants in Europe and beyond. Manufactured by our subsidiary, FNX, our modular plant designs are fully tested in-house; making for easy deployment at any production site.

- Our technology is proven and already operating in Spain and Italy—today.?

- Our management and manufacturing teams have 10+ years of industry experience.

- We make a plug-and-play product that fits in a container and is easily assembled on-site.?

- We offer scalable solutions that benefit the entire value chain, from food producers to the end consumer.

- We take on capital investment, gas sale negotiations and delivery to market.?

- Our plants can be remotely deployed to unlock stranded waste feedstock.