- Home

- Companies

- Polar Power Inc.

- Products

- Polar Power - Model 6200 Series - DC ...

Polar Power - Model 6200 Series -DC Alternators

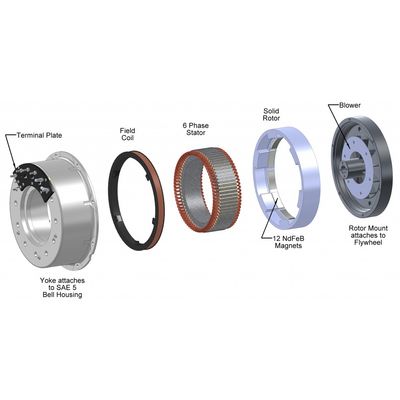

Polar Power first tested its DC Alternator using its Permanent Magnet Hybrid Homopolar (PMHH) technology in 1992. Since then numerous organizations have performed extensive testing on Polar’s generators, including the US Military. Polar Power has met these performance goals through an integrated engineering effort involving detailed analysis of engine, voltage regulation electronics, field coil, magnet, stator, rotor, and diode effects on the generators output voltage, current, and electrical quality. Polar Power selected and optimized the 6200 series alternator using our PMHH technology because it does not require brushes, slip rings, rotating fields, exciters, or field flashing. Its small and compact design allows the use of a bearing-less pancake design.

- Telecommunications

- Systems without Batteries

- Systems without Sensitive Loads

- Military APU’s

- Cogeneration and CHP

- Cathodic Protection

- High reliability and low maintenance

- High degree of corrosion resistance

- No mechanical adjustments

- Very light weight

- High quality electrical output

- Stiff voltage regulation to current demand

- Up to 94% efficiency

- Adustable Power Outputs via Engine RPM

- Wide Temperature Operation Range

(-50° to 145°F)

The permanent magnet alternator being the simplest, most efficient, and reliable of all the technologies, and the homopolar alternator providing the output regulation. The permanent magnetic portion produces the majority of the power, while the homopolar portion boosts the power produced by the permanent magnet and provides a means of voltage regulation. The system provides excellent voltage regulation in response to load transients. The homopolar alternator has the fastest response to load transients among the brushless alternator technologies.

The PMHH technology uses a solid rotor with magnets revolving around a stationary stator and field coil. The construction is extremely simple and requires no maintenance or replacement parts.

To reduce ripple and improve output harmonics, Polar Power incorporates a 6-phase stator with each phase rotated 60 degrees in a 12 pole configuration. To further improve electrical quality, the Supra controller energizes the field coil to provide a “clean” proportional output. Most other voltage regulators simply turn the field on.

The 6-phase bridge rectifier assembly is custom engineered and manufactured by Polar Power. We incorporate the most efficient Schottky diodes mounted on a large heat sink for improved cooling and installed off the alternator to reduce the negative effect on engine vibration on diode life.

Engine performance under electrical load is greatly improved due to the 12 poles, 6 phases, and proportional output voltage regulator. Under these favorable conditions, the engine steel laminations are bonded and have a smooth and even torque requirement over the 360° flywheel rotation.

- The unique alternator design allows it to operate at low engine speeds, thereby extending engine life and reducing engine noise.

- Polar Power’s PMHH alternator has no bearings, couplings, brushes, slip rings, or rotating fields. There are no alternator parts to wear out.

- The entire stator assembly is varnished dipped and baked with a polyester coating. Resistance to salt fog is very high. The coatings also protect the stator from particle abrasion and vibration.

- There are no electronic parts (diodes, etc.) nor electrical connections inside the alternator. There is nothing to short or vibrate loose inside the alternator.

- The alternator is almost impossible to damage electrically. The outputs can be shorted for a short duration without damage.

- The alternator with a Polar Power controller is thermally protected; a sensor on the yoke can alert the operator of a high temperature condition. If no action is taken, the regulator automatically reduces the output current, so the alternator will run cooler.

- The Model 250 Voltage Regulator monitors the output current through a current transducer mounted on the Diode bridge. The voltage regulator has a programmable current limit on the output. It is virtually impossible to overload the alternator or stall the engine on a properly calibrated system.

- The Diode Bridge Assembly is separate from the alternator diodes. The power loss through our 6 phase bridge is less than half that of other DC generators.

- Polar Power’s PMHH alternator is designed have an MTBF the field coil. exceeding 100,000 hours, as there are no parts which rub, off at lower frequencies, which creates ripple on the wear, or overheat under normal operating conditions.

- Corrosion is the prime reason most standby generators fail. Polar’s alternators are ruggedized for marine and agricultural applications. All components are constructed of corrosion resistant: stainless steel fasteners, hard anodized aluminum rotor mount, nickel plated magnet ring, and zinc plated yoke. Steel laminations are bonded in each laver to prevent voids. A clear coat of varnish then covers the parts for enhanced corrosion resistance.

- The alternator’s rotor is dynamically balanced to Class 3 for Low Maintenance and High Reliability