- Home

- Companies

- Dürr Systems, Inc.

- Products

- Dürr - Battery Electrode Coating

Dürr - Battery Electrode Coating

Dürr provides a comprehensive turnkey approach for producing battery electrode coated materials. Our capabilities cover both ends of the production line, as well as everything in between. We provide systems for raw material handling, slurry mixing and fluid delivery, web handling, coating and drying, solvent recovery and purification, calendering, and slitting.From a coating line that meets the basic and competitive needs of a new player in the market to a fully integrated production line for high-volume runs, Dürr Megtec is a single-source OEM that can meet all your electrode production requirements, including the support during process development. Our capabilities cover turnkey coating lines, equipment installation, start-up supervision, and 24/7 service and parts support.

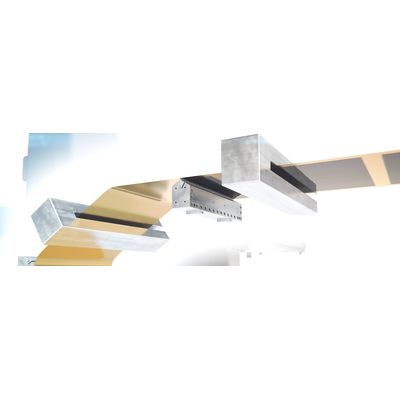

The simultaneous two-sided coating is characterized by a straight-path product flow and a single coating station. This unique process provides benefits such as a smaller overall manufacturing footprint and no edge curl after drying, and consists of a slot-die coating on a backing roll immediately followed by a tensioned-web slot-die coating to coat both sides of the foil in one pass. An air flotation dryer enables simultaneous two-sided coating as the foil is running through a non-contact drying process.

The tandem coating is based on mature technology with only one, straightforward coating process taking place. Tandem coating is less sensitive to foil quality and thus optimized for large foil widths. The process is characterized by a slot die coating on a backing roll to coat one side at a time. This is more common for high volume manufacturing. Either roll support or flotation drying can be used which provides some flexibility to the customer.

- Coat weight 70-300g/m2 dry

- Coat weight precision < +/- 1%

- Sharp edges < 3mm

- Dimensions & register +/- 0.5mm