Ecochlor - Model PALS -Aspirated Hull Air Lubrication System

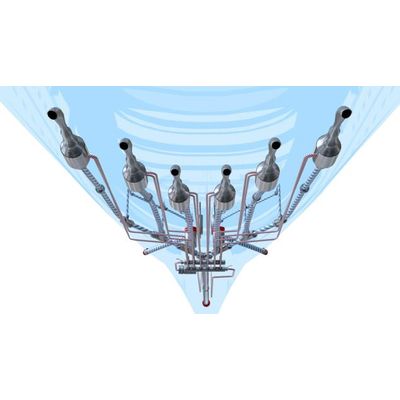

Armada Technologies has developed the world’s first passively aspirated hull air lubrication system (PALS). By taking advantage of passive physical phenomena, combined with the forward motion of the vessel, the Armada’s PALS™ system dramatically reduces the power required for bubble production and distribution under the hull. PALS™ also automatically adjusts in real time to a wide range of ship operating conditions.

First generation hull air lubrication systems use multiple power-hungry air compressors to create and distribute the lubricating bubbles. In contrast, the Armada PALS™ system does not use compressors, thereby significantly reducing the power requirements of the system.

PALS™ uses a carefully designed venturi combined with the forward motion of the ship to passively create the optimum size of lubrication bubbles. The net result is superior lubrication over a wide range of speed and depth variables, which when combined with low power consumption offers the vessel owner savings of up to 12% in fuel usage.

Hull air lubrications systems are recognized under the IMO Energy Efficiency Design Index (EEDI) for newbuilds. Air lubrication retrofitted to existing vessels will also be a key factor in improving their efficiency ratings in the IMO’s upcoming Energy Existing Ship Index (EEXI).

- Low power requirement for system operation

- PALS™ venturi design creates optimum bubble size and volume

- System automatically self-controls over a wide range of operating variables

- Simple to use with low maintenance

- PALS™ is easy to install

- Given that water friction can account for “up to 85% of a hull’s total resistance” an Armada PALS™ installation offers shipowners a reduction in requisite power to an ordered speed, allowing for a higher speed for a specified power or some combination of both these benefits. In either case, a dramatic reduction in fuel consumption and associated impact on operations can be realized.

- The Armada PALS™ unit is user-friendly and needs no additional staff to maintain the system. Plus, the system allows for a simple integration in the vessel operation. It can be fitted in a routine dry dock and more than 50% of the work can be done when the vessel is in service.