- Home

- Companies

- Cox Research & Technology Inc.

- Products

- Camo - Electrical Control Panel ...

Camo - Electrical Control Panel Hardware

In the past, troubleshooting of electrical control panels has only been done in the field and in all types of weather conditions. The CAMO® system was designed and developed to specifically address the problems associated with both maintenance and mitigation.

NOW, THERE IS A SOLUTION

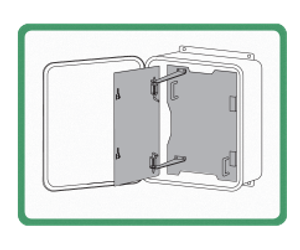

The CAMO® system is control panel hardware with a means and method of quick and easy removal of the entire interior. The control enclosure is left in place with conduits and external wiring attached. The inner door with mounted components can be separately removed while all external wiring is easily disconnected using separable terminal strips. The user may have spare assemblies placed in storage and when maintenance is required, the entire assembly can be rapidly switched out.

CAMO® – Control Assembly Maintenance Option: A second version of the CAMO® system is one for maintenance purposes only. Multiple stations can contain identical controls. The owner may have spare assemblies placed in storage and, when maintenance is required, the entire interior assembly can be rapidly switched out allowing the malfunctioning unit to be brought back to the repair location for overhauls -or- sent back to the manufacturer for repair -or- complete refurbishing. The systems are available for use in selected stainless steel, non-metallic, painted steel and explosion-proof enclosures.

CAMO – Control Assembly Mitigation Option

CAMO has been funded by agencies of the U.S. Government for damage maintenance in areas prone to natural disasters. The patented CAMO system is control panel hardware with a means and method of quick removal of the entire interior, or portions of the interior, of the panel, complete with all components which can be damaged by floodwaters or other natural disasters before they occur. Replacement and removal is simple: once the interior is detached, the CAMO® control enclosure is left in place with conduits and external wiring attached. All control and power wiring is disconnected using separable terminal strips. To hasten this process, special handles are placed at optimum locations on the back plate to facilitate quick and safe withdrawal of the assemblies, clocking disassembly at less than 5 minutes. The assemblies are placed in permanent containers designed for their storage and transportation to a safe location until after the disaster event. In flood prone areas, special CAMO drain and vent devices are installed on the fixed external enclosures to allow fast-rising and falling water to enter and exit the enclosure, thus preventing enclosure damage due to large differential pressures. We have designed the CAMO® system to be as efficient as possible in the field for all service and upkeep.

In the past, troubleshooting of electrical control panels was a real problem. It could only be done in the field and had to be done in all types of weather.

Now, there is a solution, the patented camo system:

The CAMO system is control panel hardware with a means and method of quick and easy removal of the entire interior or portions of a control panel complete with all mounted components. The control enclosure is left in place with conduits and external wiring attached. The user may have spare assemblies placed in storage and when maintenance is required, the entire interior assembly can be rapidly switched out. The malfunctioning unit can be brought back to the repair location for repairs or complete refurbishing using the original equipment manufacturer (OEM) parts. The systems are available for use in selected stainless steel, non-metallic, painted steel and explosion proof enclosures.

- The control enclosure is left intact, with all conduits and external wiring attached.

- All external wiring is easily disconnected using separable terminal strips.

- The inner door with components mounted can be separately removed.

- Special handles, placed at optimum locations on the back plate, allow quick removal of the entire assembly.

- The entire disassembly and re-assembly process can be done in less than 5 minutes.

Damage Mitigation

The CAMO system was originally designed for mitigation of sewage pump station control panel damages caused by floodwaters or other natural disasters and is being used for such purposes in many locations. In the case of flood mitigation, the enclosure interiors can be removed before the disaster occurs.

The swing panel with the most expensive electronic components such as PLC’s, radios, etc. can be quickly removed and the panel placed in the emergency operating mode until the emergency is over. In cases where mandatory evacuation is required, the entire enclosure interior with all components can be removed. Special fill, drain and vent devices are used to allow fast rising and falling water to enter and exit the enclosure, thus preventing enclosure damage due to large differential pressures. After the disaster event, the removed assemblies can be quickly re-installed and the station put back into normal service. Special permanent aluminum containers can be supplied for the panels to be transported and stored in a safe area. These special containers can also be furnished for storage of spare interior assemblies.

Use In Classified Areas

An example of use in a classified area is where the entire interior of the enclosure with components mounted can be quickly removed and brought to a test bench outside of the classified area for adjustment or repair then rapidly reinstalled. This prevents many special precautions and extra personnel required for making repairs and adjustments in classified areas in the field. Also, complete spare interior assemblies can be on hand without the need of expensive spare explosion proof enclosures which, many times, cost more than the interior components.

Assembly Removal/Installation

- Turn off power to control panel.

- Open door and verify power is off.

- Unplug all external wiring.

- Unplug inner swing door wiring.

- Pull down swing door spring latches and remove swing door.

- Remove four (4) back-plate nuts and grab back-plate handles.

- Pull entire back-plate assembly with all components attached out of the enclosure.

- Reverse procedure for re-installation.

Recommended Specifications

All control panels shall be designed such that the entire interiors complete with all components can be quickly and easily removed and re-installed without disconnection of the external conduits and wiring from the enclosure. The inner swing door shall have spring latches and shall be independently removable. Special handles placed at optimum locations on the back plate shall be utilized for removal of the interior. Inner swing door shall be 1/8” thick aluminum with 1/4” thick stainless steel support brackets. Back plate shall be 3/16” thick aluminum with cutouts positioned at normal locations for exterior penetrations. All control and small power wiring to be disconnected shall be by separable terminal strips. Interiors shall be designed to fit specific enclosure manufacturers sizes and types. The Contractor shall utilize the CAMO system by Cox Research and Technology, Inc., Baton Rouge, La.