- Home

- Companies

- Hosokawa Micron B.V.

- Products

- DMR-H - Flash Dryer

DMR-H - Flash Dryer

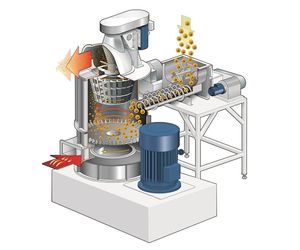

The flash dryer from Hosokawa is the first drying system of its kind to be patented anywhere in the world. It has been developed to combine drying, de-agglomeration/milling and classifying in one piece of equipment. The latest edition of this flexible drying technology is the Drymeister (DMR-H): a flash dryer that can dry temperature-sensitive products, safely, even under increased temperatures, in a matter of seconds! The Drymeister can handle moisture content fluctuations from a few % up to more than 80% in suspensions, slurries, pastes, filter cakes and wet powders. It requires 75% less space and uses about 30-40% less energy per kilogram of evaporated water.- Ultra fine regular end product

Due to its specially designed dispersion rotor, our flash dryers are able to produce ultra-fine powders in one step from suspensions, slurries, pastes and dough, filter cakes or wet powders. - High evaporation capacity

Due to the combination of high ΔT with a good dispersion of the wet product in the air, our flash dryers can evaporate large quantities of liquids. - Compact design

Compared to other direct drying technologies, the flash dryer requires up to 50% less space. - Multi-purpose

Filter cake or slurry, in the same machine. Therefore with the Drymeister unlimited mechanical dewatering is possible previous to the final drying stage. - Easy access

Either for cleaning, inspection or maintenance inside the dryer, our flash dryers offers the best accessibility from the market, regardless what size. - Various systems available

Open, closed- and recycle system concepts.

The wet material is fed through customised feeding systems into the grinding and drying section of the dryer's main body. The grinding rotor disperses the wet material into very fine particles and the fine particles are fluidised in the grinding chamber by temperature-controlled, hot gas coming in from the air heater.

The hot air (or inert gas) can be heated up to 650 °C and as the wet product is dispersed, it is reduced in size in the bottom section of the dryer. The system is kept under a negative pressure by the exhaust fan and the surface area of the product is increased enormously so that water (or other solvents) is evaporated instantaneously.

The dry and fine particles are conveyed with the gas stream to the top section of the dryer where a separator classifies the particles by size. Then the particles pass the classifier at the set cut point and are conveyed with the exhaust air to a powder air separating system like the cyclone, cyclone filter or cyclone scrubbers.

The flash dryer retains a fluidised bed of product in the drying chamber to ensure a low level of adhesion of wet material on the inside wall of the drying chamber. Moreover, process parameters like classifier speed and outlet temperature can be adapted to control moisture content and particle size of the end product.