- Home

- Companies

- Enviropol Engineers Pvt.Ltd.

- Products

- Enviropol - Flash Dryer for Bagasse

Enviropol - Flash Dryer for Bagasse

Bagasse and its conservation has become a necessity for up coming sugar factories moving towards co-generation. Enviropol – Flash Dryers for Bagasse maximizes the generation of heat energy from available system through substantial reduction in moisture content.

- High reduction in Moisture – up to 15 units

- Higher heat Transfer – Adiabatic process

- Short residence Time – Flash Drying

- Regulated Feeding – No threat to Chocking

- High efficiency Cyclone – Negligible loss of fine Bagasse

- No air infiltration – Restricted Fire Hazard

- Corrosion/erosion Resistant – Superior material of Construction.

- Enhanced Steam Generation

- Increased Boiler Efficiency

- Faster Boiler Pick up

- Reduced Excess air in the Fumace

- No adverse effect on Boiler

- Quicker return on Investments

- Prolonged Co-generation through Bagasse Saving

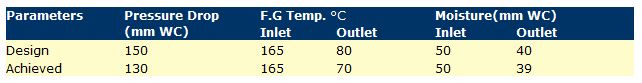

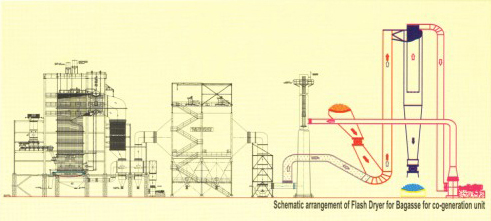

The hot and de-dusted flue gas from the boiler are made to pass through the flash tower under induced / forced draft. The wet mill bagasse is fed through a rotary air lock feeder at the bottom of the tower. It is then carried upward in a co – current mode with the hot flue gas at a calculated velocity bassed on Average Particle Residence Time (APRT). During the process, bagasse moisture evaporates and the dried bagasse is subsequently separated through a high efficiency cyclonic separator.

The dried Bagasse is continuously evacuated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the Boiler. The flue gas are released to the chimney through ID fan. Adequate automation is proper interlocking and protections.