- Home

- Companies

- Guangdong Lyric Robot Automation Co., ...

- Products

- Fully Automatic Ultra-Fast ...

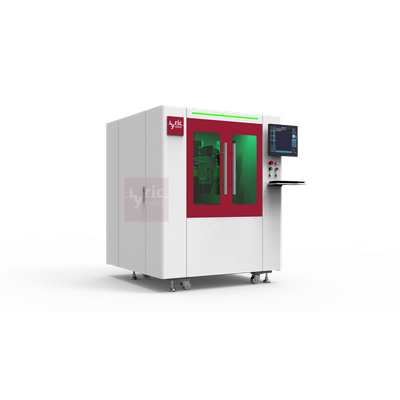

Fully Automatic Ultra-Fast Nondestructive Slicer

The laser system is used for rapid splitting and separation on the assembly line, and uses non-destructive technology to split the cells into specified specifications. Product highlights include horizontal reverse detection judged by detecting the direction of the grid line, feeding debris detection with 5 million pixels (conventional) to detect edge chipping and missing corners, position information acquisition with feedback to the laser system for cutting position compensation achieving repeat cutting accuracy of ≤0.1mm, quick product switching, and quick rejection of unqualified products.The laser system is used for rapid splitting and separation on the assembly line, and uses non-destructive technology to split the cells into specified specifications.

The horizontal reverse detection is judged by detecting the direction of the grid line;

Feeding debris detection: 5 million pixels (conventional), can detect edge chipping and missing corners;

Position information acquisition, the offset information (X,) is fed back to the laser system through the positioning of the silicon wafer, and the repeat cutting accuracy is ≤0.1mm for cutting position compensation;

Quick product switching;

Unqualified products can be quickly rejected.

Cell size: 156*156-230*230

Thickness: 150-300μm

Capacity: 7200 pieces/hour (whole piece)

Cutting method: Galvo grooving + split cutting method

Fragmentation rate: ≤0.05%

Yield: ≥99.5%

Failure Rate: ≤1%

Laser wavelength: 1064nm