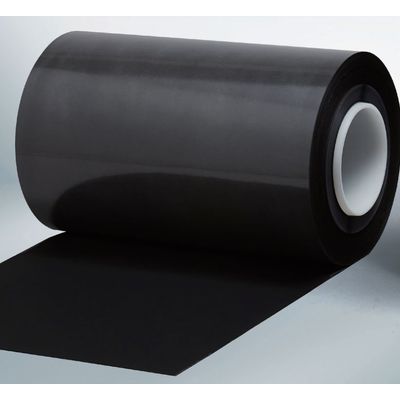

Gas Diffusion Layer (GDL)

We have developed a range of MPLs that can operate under various conditions. We can deliver the MPL that can best meet the needs of our customers.

The gas diffusion layer is a core component of hydrogen fuel cells that provides a steady supply of reactant gas, which in turn acts as a pathway from the flow field channel to the catalyst layer, and removes the heat created from electrochemical reactions by transferring it to the separator plate via conduction.

We designed a GDL using a non-woven material to allow fuel and byproducts to move with ease within the GD layer. We achieved this by controlling certain properties of the gas diffusion backing layer (GDBL) and the micropore distribution of the microporous layer (MPL). We also designed our GDL so that there is lower interfacial resistance between the catalyst layer and the current-collecting bipolar plate.

Our products have uniformity in their properties including thickness, micropore distribution, porosity, and smoothness. We also control the microporous structure of the GDL so that it can meet the needs of the customer and perform under intended conditions of the fuel cell.

- JNT20 : thin, high MEA performance, fit for a DMFC system

- JNT30 : designed for fuel cells in stationary use (buildings), high MEA performance even in fuel cell environments with a high relative humidity.

- JNT40 : Around 400 um in thickness, low rate of compression and bending, adjusted density to improve mechanical properties

The gas diffusion backing layer is a thin but uniform layer of carbon paper made with carbon fiber and binding resin. Upon binding, the resin undergoes carbonization, also turning into carbon. The GDBL is coated with a layer of fluorine polymer and exposed to heat treatment to become water repellent. Our company can control the PTFE so that it has a 5~40 weight ratio with the GDBL. A fuel cell’s GDL comprises the GDBL and the microporous layer (MPL), which consists of carbon black and a binding agent.

- Original technology & fully in-house production process, starting from carbon dispersion to final stages.

- In-house production of MPL coating slurry

- Products can be tailored to customer needs by controlling properties such as thickness, porosity, fiber orientation, and conductivity.

A3

General products

Fuel cells for buildings

Fuel cells for mobile devices

B1

DMFC Anodes

PEMFC for dry conditions

A6L

Low humidity

FCV

A6H

High humidity

FCV

UA6,UA7(개발 중)

High durability

FCV (commercial automobiles)