- Home

- Companies

- ARC Southern Energy LLC

- Products

- ARC - Gasification Using Plasma Arc ...

ARC - Gasification Using Plasma Arc Technology

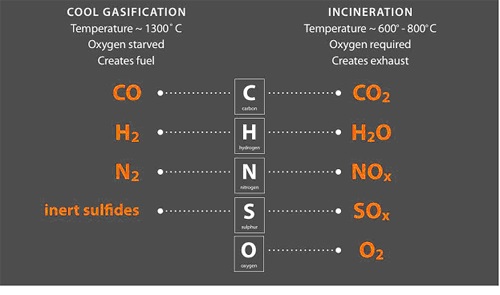

Gasification is a process that converts carbonaceous materials, such as coal, petroleum, biofuel, or biomass, into carbon monoxide and hydrogen by reacting the raw material, such as house waste, or compost at high temperatures with a controlled amount of oxygen and/or steam. The resulting gas mixture is called synthesis gas or syngas and is itself a fuel. Gasification is a method for extracting energy from many different types of organic materials. In principle, gasification can proceed from just about any organic material, including biomass and plastic waste. The resulting syngas can be combusted. Alternatively, if the syngas is clean enough, it may be used for power production in gas engines or gas turbines.

What is Plasma Arc Gasification?

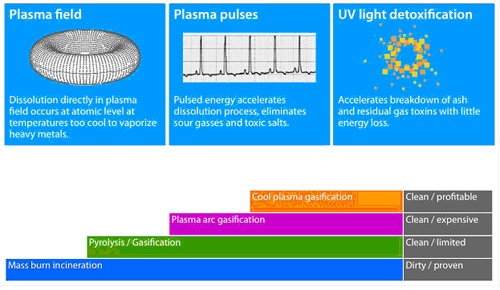

Plasma arc gasification is a waste treatment technology that uses electrical energy and the high temperatures created by an electrical arc gasifier. This arc breaks down waste primarily into elemental gas and solid waste (slag), in a device called a plasma converter. The process has been intended to be a net generator of electricity, depending upon the composition of input wastes, and to reduce the volumes of waste being sent to landfill sites.

In a nut shell what is our technology?

When waste is gasified, the volume of solid waste is reduced by about 95%.

The primary output is valuable syngas that can be converted to clean energy.

The remaining ash is a commercial product. Gasification is the central hub of several alternative energy technologies.

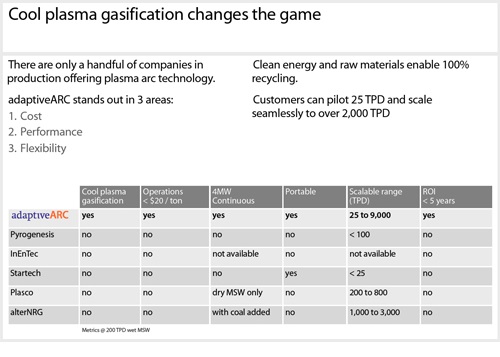

The technology we provide is called cool plasma gasification, which is both clean and profitable.

Plasma arc gasification generates the highest syngas yields and is recognized as the cleanest way to convert energy from biomass, waste, or coal feed stocks. However, to date the process has been too costly. The proprietary technology that we market with Adaptive ARC called Cool Plasma Gasification technology changes the game and provides the same benefits at a 65% reduction in capital cost. The result is the most economically compelling gasification alternative in the marketplace.