- Home

- Companies

- Quidnet Energy

- Products

- Quidnet - Geomechanical Energy Storage ...

Quidnet - Geomechanical Energy Storage (GES) System

The energy system is fundamentally changing. Cost-effective long-duration storage is essential for integrating and expanding the use of intermittent, renewable energy resources, such as wind and solar. Traditional pumped hydro storage is the largest and most cost-effective form of long-duration energy storage today. However, due to dependency on elevated terrain, pumped hydro storage has many constraints. Lithium-ion batteries are effective at storing energy for 2-6 hours, but they become prohibitively expensive at longer durations. Quidnet Energy is pioneering a novel form of energy storage – Geomechanical Energy Storage (GES) – a modular, standardized solution that is widely deployable at a much lower cost.

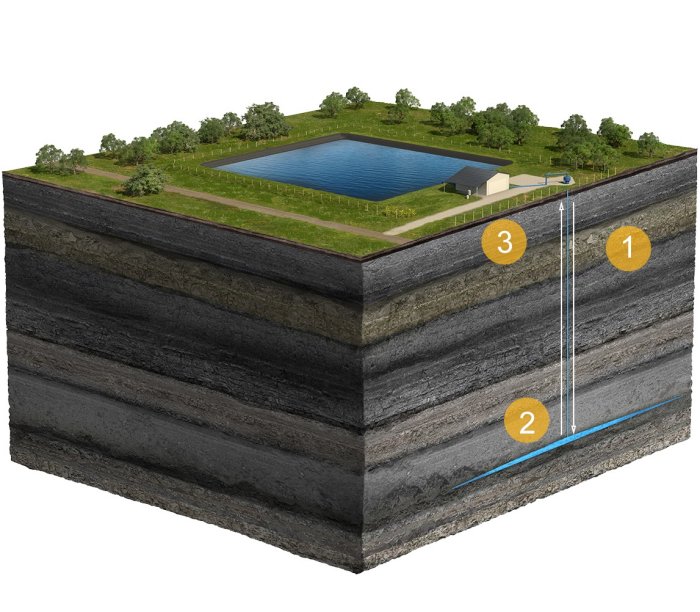

- When electricity is abundant, it is used to pump water from a pond down a well and into a body of rock.

- The well is closed, keeping the energy stored under pressure between rock layers for as long as needed.

- When electricity is needed, the well is opened to let the pressurized water pass through a turbine to generate electricity, and return to the pond ready for the next cycle.

Production of Geomechanical Energy Storage modules follow a standardized process and employ a universal basic design that is configured for a given project site or region. Multiple modules of the same design and configuration are produced to meet the total target capacity of the project site.

Parts Procurement

Materials and subcomponents used in the GES module production process, such as pumps, motors, turbines, pipes, liners, and instrumentation are procured.

Subsystem Production

The main Subsystems of a GES module – the Well, Surface Water Storage, and Power Conversion – are produced.

Well. Segments of steel piping are joined and lowered into a well drilled on the project site. The piping is fixed in place with cement, a physical connection is made to the surrounding rock body, and additives are injected to ensure proper hydraulic functionality.

Surface Water Storage. Plastic liners are attached to an Earthen pond created on the project site, along with piping and instrumentation, and filled with water.

Power Conversion. Mechanical subcomponents (e.g., pump / turbine) are connected to power subcomponents (e.g., motor / generator) and tied together with piping and associated instrumentation and controls.

System Integration and Commisioning

The Well, Surface Water Storage, and Power Conversion subsystems are connected with each other and tied to the site power connection. The GES system then undergoes routine testing for commissioning and start-up operations.