chengdu purui polymer engineering co.,ltdPurui Plastic & Rubber Machinery Co., Ltd

Purui - Model SJ -HDPE PP Plastic Bottles/Basin/Bucket Pelletizing Extruder

HDPE PP plastic bottles/basin/bucket pelletizing extruder to recycle waste PP/HDPE plastic shampoo bottle, container, trash can, bucket and other hollow board material, chemical bucket, barrel, milk bottle, basin.

Most popular related searches

Features of crushed flake granulator:

- Higher output and lower consumption (0.27kwh/kg to 0.35kwh/kg)

- To compare with other supplier, 20% output more than our first -generation products

- To compare other suppliers, 15% less than consumption our first -generation products

- 2 labors operating the whole line

Applications of plastic bucket, basin, barrel, milk bottle, chemical bucket, container pelletizing/granulating extruder:

- Applicable plastic materials: PE, HDPE, LDPE,PP, etc

- Material shapes: rigid flakes, crushed flake and washed flake

- Note: depending on different material properties, various downstream equipment are needed.

How it works

- Screw charger uploading the material by timer

- Feeder and extruder is controller by frequency inverter,

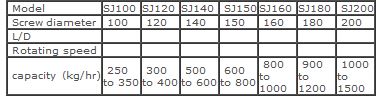

- Different L/D for different material

- Nature degassing, vacuum degassing adopting for moisture

- Water ring die face cutting for perfect pellets shape