- Home

- Companies

- CASIS Group Limited

- Products

- Heat Resistant Silicone Rubber Membrane ...

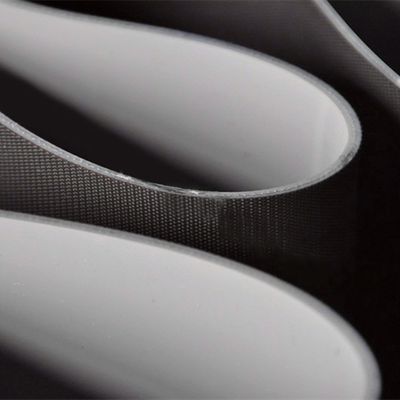

Heat Resistant Silicone Rubber Membrane For Solar Panel Laminator

Heat Resistant Silicone Rubber Membrane For Solar Panel Laminator. Although also called diaphragms, sheets, or membranes, the solar panel industry tends to use the term membrane. Diaphragms for PV module manufacture Special covering layer (black) on silicone backing (grey) Bond of the two layers cannot be separated mechanically Black covering layer is resistant to decomposing outgassing during lamination process Durability results in longer machine running times and thus shorter set-up times Constant quality thanks to quality management. KS-EXR668 is our fifth generation silicone sheet series, it’s a specially developed membrane consisting of a silicone backing material and a unique covering layer. This covering layer is extremely resistant to outgassing and related decomposing processes of EVA films. This makes Lamination particularly durable and increases your machine running times.

Corrosive attack on Silicone Sheets

World-wide producers of thin film and crystalline solar panels face corrosive attacks on Silicone Sheets used on lamination equipment.

During the lamination / encapsulation process of EVA volatile outgassing occurs. Outgassing refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Sheets. This corrosion manifests itself in surface degradation (cracks) + excessive stretching and sagging.

KS-EXR668 series Silicone Sheet is a hybrid material that resists the deterioration caused by EVA outgassing. In addition it is a really tough material with both tensile strength and tear resistance higher than traditional Membranes materials.

KS-EXR668 series Silicone Sheet has very tight elongation features – resistant to excessive stretching and sagging. Customers’ feedback indicates that our silicone sheets may give up to 50% longer life than some traditional Diaphragm materials – obviously dependent upon type of module, encapsulant and conditions.