- Home

- Companies

- Douglas Electrical Components

- Products

- Douglas Electrical Components - Model ...

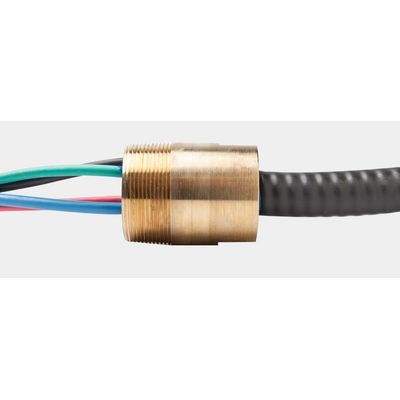

Douglas Electrical Components - Model DuctorSeal Series -Hermetic Wire & Cable Feedthroughs

DuctorSeal hermetic wire feedthroughs and sealed cable assemblies provide custom, liquid- and gas-tight electrical pass-throughs for various applications. Our hermetic feedthroughs come pre-wired and pre-tested, ensuring seamless drop-in use. DuctorSeal supports virtually any electrical connection combination on vacuum and atmospheric sides, accommodating conductor counts of up to 3,000 wires for demanding applications.

Ultimate Design Flexibility

Each end of the bulkhead can be customized to feature wires, jacketed cables, or connectors, with the hermetic sealing point located within the epoxy of the bulkhead at the conductor. DuctorSeal’s epoxy-sealed feedthroughs are designed to meet leak-rate requirements, even in stranded wire applications, and comprise precision-machined housings made from materials such as aluminum, titanium, stainless steel, brass, specialty alloys, and plastic. A variety of mechanical interfaces are available including threaded connections, flanges, and customized fittings.

To simplify installation, Douglas Electrical Components offers integrated terminals and connectors at each end of the wires and cables, saving time on the factory floor or in the field. If you’re potting cables in your operation, Douglas offers the expertise to do this process efficiently, with fully tested assemblies ready for use. Virtually any connector type can be integrated, with Douglas sourcing all components according to your needs.

Our custom hermetic feedthroughs can withstand a range of environments, with vacuum capabilities from 1×10-10 Torr to pressures of 15,000 psi. Operating temperatures range from 4 K (LHe) to 200°C. High voltage and low cross-section sealed wire feedthroughs operating up to 30kV-DC are also available.

Designs for Hazardous Locations

DuctorSeal hermetic wire feedthroughs are available as standard and custom options for hazardous locations. We offer UL/cUL Class I Division 1 explosion-proof conduit seals with wires from 24 AWG to 3/0 AWG in various conductor lengths and colors. Additionally, our team can custom-design a feedthrough to help achieve an explosion-proof rating for your system, analyzer, sensor, or transmitter. Contact us with details on your application to get started.

- Uses the same wire and insulation types already approved for use elsewhere in your system

- <1×10-9 cc/sec per feedthrough

- Pressures of 15,000 psi

- Operating temperatures range from 4 K (LHe) through high temperatures of 200°C

- High-voltage cables up to 30,000 V

- Full cable harness options with connectorization available

- NPT

- Face seals

- Radial O-rings

- SAE

- QF/KF flange

- ANSI flange

- Custom options available

- Individual wires (PTFE, PVC, etc.)

- Jacketed cable

- Coaxial feedthroughs

- Thermocouple

- Customized assemblies with integral connectors

- Visit our OptiSeal page for Fiber Optic Feedthroughs

- ISO 9001:2015

- ISO 14001:2015

- ITAR DDTC Registration

- UL/cUL 1203, UL 886, UL 674, and UL 913