Rongsheng Group

- Home

- Companies

- Rongsheng Group

- Products

- Rongsheng - High Alumina Refractory ...

Rongsheng - High Alumina Refractory Brick

FromRongsheng Group

High alumina refractory brick is a silicic acid refractory material, the softening temperature under load is 1420-1550°C, and the load temperature will increase with the increase of the ratio of aluminum to silicon.

Most popular related searches

- Brand: Rongsheng

- Factory History 20 years

- Exporting countries: 80+

- Delivery time: 7-12 days

- Whether to support customization: yes

- Sample: samples can be provided

- Types of high alumina bricks: first level, second level, third level

- Factory: Welcome to visit the Rongsheng factory!

Advantages of high alumina bricks

High alumina bricks have good resistance to acid and alkaline slag, corrosion and oxidation of molten metal, and reduction reactivity, and have good thermal shock resistance, but are lower than clay.

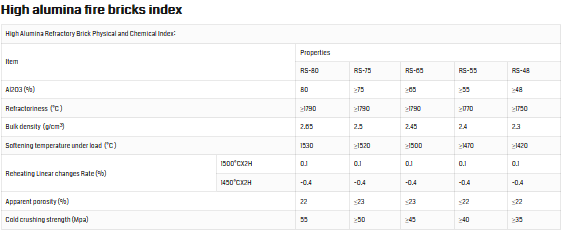

Three grades of high alumina refractory bricks

- The Al2O3 content of the first-grade high alumina brick is >75%

- The Al2O3 content of the secondary high alumina brick is 60-75%

- The Al2O3 content of the third-grade high-alumina brick is 48-60%

Customized aluminum fire brick

The refractory material factory supports customized aluminum fire bricks. You can send us the size or design drawings of your aluminum fire brick, and we will evaluate them and then make a production plan for you.

- High refractory temperature

- Good strength

- Chemical corrosion resistance

- Good thermal conductivity

- Long service life

- Wear-resistant