Guangzhou Devotion Thermal Facility Co., Ltd.

- Home

- Companies

- Guangzhou Devotion Thermal Facility ...

- Products

- Devotion - Horizontal Gas Fired Steam ...

Devotion - Horizontal Gas Fired Steam Boilers

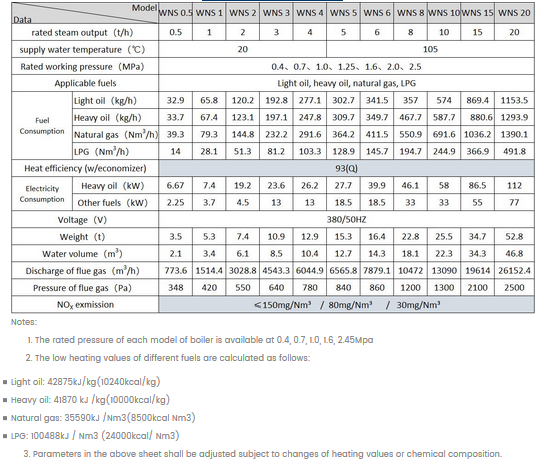

DEVOTION WNS series Gas Steam Boilers are internally fired, three-pass and wet back shell boilers. Rated output(ton/hour): 0.5,1,2,3,4,5,6,8,10,15,20. Customer tailored design is available.

Most popular related searches

steam boiler

gas steam boiler

fire tube boiler

gas fired steam boiler

boiler firing

boiler room

boiler tube

gas boiler

heating water system

boiler controller

-

Item No.:WNS Gas

-

Payment:TT, LC at sight

-

Product Origin: China

-

Color: Blue and White

-

Shipping Port: Guangzhou, Shenzhen

-

Min Order: 1

-

Lead Time:30-45 days

- Industrial users: pharmacy, papermaking, tobacco, textile printing and garment industries etc

- Civil users: catering, laundry room, disinfection(hospital), sauna etc

- Through vapor-water heat exchanger, the boilers can heat the water inside heating system for air conditioner, radiators and floor heating etc

- Provide power to LiBr absorption refrigerator with pressure P=0.6-0.8Mpa

- Devotion Steam Boilers are constructed availing internationally tried and tested design of three pass, wet back structure to deliver higher safety and reliability

- The specially-desgined large combustion room enlarges the heating area by hearth radiation while lessens the boiler size and reduces NOx emission;

- The corrugated hearth makes it a safer boiler for users.

- The threaded smoke tubes improve heat transfer, thus increase the boiler’s thermal efficiency;

- Multi levels sealing applied on front and rear smokeboxes, no smoke leakage;

- Lager steam space, fine quality steam;

- High-efficient insulation materials, low boiler surface temperature. The heat dissipation loss may be ignored;

- Boiler control system can run for a long time under high temperature and humidity.

- Multi-level interlock protections available like water level, steam pressure, gas pressure and so on.

- Devotion boilers are manufactured and tested in compliance with national standards. All pressurized parts are made from high quality steels from well-known steel plants.

- Each boiler must undertake a series inspection and test before delivered to the user, such as Non-destructive test and hydraulic tests.

- All components and auxiliary equipment like burners, pumps, water level gauge, safety valves are supplied by renowned brands.

- Easy maintenance with man hole and hand holes.

- A patented economizer (optional) can save 15% fuel and reduce noises.

- Unless space of boiler room is limited, horizontal boilers rather than vertical boilers are recommended because horizontal boilers have higher efficiency.

- In case steam pressure is above 1.6Mpa, water tube boilers or water- fire tube boilers are recommended instead of Fire Tube Boilers.

- Should only steam temperature matter while no requirements for pressure, it is better to choose superheated Steam Boilers.

- For industrial users, as per requirements of production process, certain margin should be allowed besides resistance loss of pipeline and boiler room.