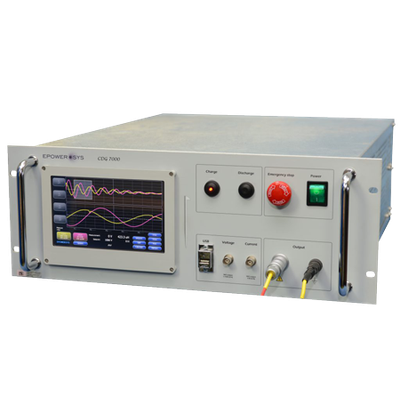

EPOWERSYS - Model CDG 7000 -Impulse Winding Tester

CDG 7000 is presently of standard use at CERN for testing all magnets in the accelerators and experimental lines of any type (normal conducting and superconducting, small and large). CDG 7000 is easy to use and you will save money. The insulation faults between turns are detected either by comparison of the reference’s coil waveform with the coil under test or by observing a change in the ringing frequency of the DUT. You will be able to see faults which you might be missing with your existing tester. You need at least 1µF and 2kV to detect some faults before a problem in operation. CDG 7000 is equipped with: USER-FRIENDLYNESS. You do not need high voltage skilled operators to use it.

CDG 7000 is presently of standard use at CERN for testing all magnets in the accelerators and experimental lines of any type (normal conducting and superconducting, small and large).

- 2 µF –internal capacitance

- 7 kV –output voltage

- 49 J –pulse energy

Why 2µF

Experience with magnets shows that working with testers below 1µF and 2 kV, it is almost impossible to see many faults. These faults may not be evident during the execution of the test but may appear after an already short period of operation. When testing with other instruments with smaller capacitance we could not see many of the defects seen with 2µF. "To trigger a fault which is not a fully zero resistance fault you need enough energy, which means a bigger capacitor.”

Why bidirectional

The existence of a bidirectional switch between the tester and the coil allows to create a resonant circuit with the external inductance and the internal capacitor bank. Otherwise the coil would resonate with its own parasitic capacitance, much smaller than the capacitor bank. A bidirectional switch is needed so that the coil resonates with the large capacitor bank instead of its own small parasitic capacitance.

Quality control

Running this test on every coil produced as a quality control, prevents the integration of bad coils into your magnet, motor, transformer.

Optimize your production costs

Use this surge tester to check if you can reduce insulation and therefore volume and raw materials costs in your electrical machine. · Dimension of your coil · Raw Material costs

The best diagnosis

The insulation faults between turns are detected either by comparison of the reference’s coil waveform with the coil under test or by observing a change in the ringing frequency of the DUT.