- Home

- Companies

- Arena Comet NV

- Products

- Arena - Model Santana (A) - Industrial ...

Arena - Model Santana (A) -Industrial Pyrolysis Ovens

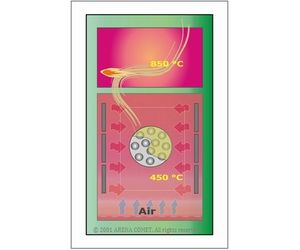

Santana (A) systems work according to the same principle as the Diablo but are usually employed for larger parts. The door slides completely out of the cleaning chamber and is easily accessible from both sides using a hoisting system or forklift to load the parts. Santana pyrolysis ovens are designed for paint stripping and removal of plastic, paint or removing any organic coating from large metal tools and parts. Typical cleaning time is 6 to 10 hours, depending on the amount of coating.

- thermal cleaning of injection molding machinery,

- cleaning of spinnerets, screens, nozzles

- cleaning of extrusion die, breaker plates, screws

- cleaning blow molding machine parts

- cleaning of hot-runners, electrical motors,

- paintstripping of hooks and racks, jigs

-The termperature control as well as the atmosphere inside the cleaning reactor are accurately controlled by an integrated programmed logic controller (PLC) for fast and thorough cleaning.

-Prior to insertion of the parts, the reactor of the pyrolysis oven can be pre-heated up to a stand by temperature or one can choose to load the parts-to-clean in cold condition.

-The loading frame (pneumatic door) slides out of the cleaning chamber when operated. The loading frame is now easily accessible from different sides to load the contaminated parts. Now parts can be loaded on to a loading platform.

-Multiple cleaning cylces can be programmed. The door is closed and the cleaning cycle will be activated automatically. When the cycle has come to an end, depending on the programmed parameters, the unit resumes stand by operation and the cleaned parts can be unloaded, or it cools down.

-The cycle itself can be freely programmed by a six stage cycle. Each stage of the cycle can be activated or tuned off, especially skipping the heat up phase and/or melting phase.