- Home

- Companies

- Vesuvius plc

- Products

- Ingot Mould

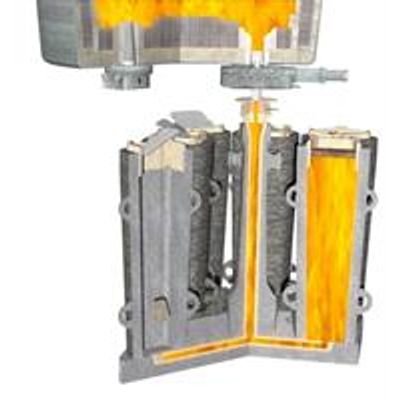

Ingot Mould

When steel is poured into the ingot mould, progressive solidification starts from the walls and the base of the mould, moving inwards towards the thermal centre or axis. The liquid steel decreases in volume during and after solidification and there is insufficient solid metal to fill the shell first formed. The result is a body of steel with cavitation or in the region of the last metal to solidify. This is not the case with rimming steel where the shrinkage is compensated for by the formation of gas blowholes.

The severity and distribution of this, depends on several factors including the quality of steel, superheat at the time of pouring, method of pouring (whether direct or indirect) and the dimensions and taper of the mould. Such cavitation is also associated with impurities, which concentrate, by segregation forming an undesirable distribution of undesirable elements in the final product.

It is thus important to influence the amount and position of cavitation by reducing it to a minimum and locating it where it will be least harmful in the solidified ingot.