- Home

- Companies

- Imperix Ltd

- Products

- Imperix - Model B-Board PRO - Inverter ...

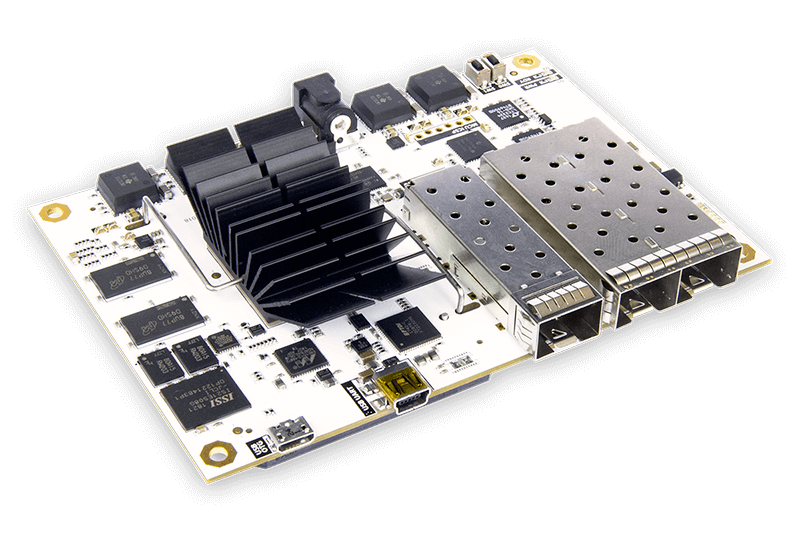

Imperix - Model B-Board PRO -Inverter Control Board

The B-Board PRO is an embeddable inverter control board that can be fully programmed using Simulink, PLECS, or C/C++. It operates identically to the B-Box RCP prototyping system.

Our programmable converter control module, based on Xilinx Zynq, can have both its DSP and FPGA sections fully customized using our software development environment. It is ideally suited for demanding power electronic applications and advanced converter control techniques, which require powerful computational capabilities and complete software/firmware flexibility.

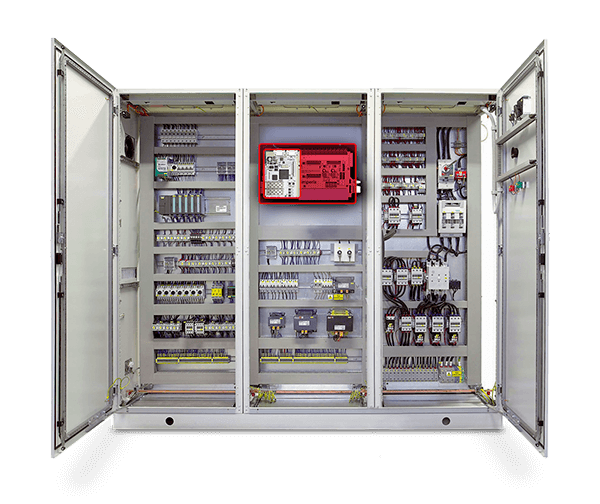

Typical applications include industrial inverters and rectifiers, motor drives, multilevel inverters, and all or distributed control systems. That said, our inverter control module can be involved in almost all applications where a fully programmable digital controller is needed.

Our rapid prototyping controller offers the very same performance as the control module, but with some additional flexibility that is tailored for R&D purposes, contributing to accelerating product development.

Thanks to the exact equivalence between both programmable controllers, control software that was previously developed on B-Box can be instantly ported on B-Board. In fact, the very same bitfile can be used!

The B-Board PRO possesses just what is needed for embedded control applications. It is small enough to be integrated directly within power converters, yet powerful enough to support advanced applications.

System on chip: Xilinx Zynq XC7Z030-3FBG676E

Digital outputs: 16x Electrical (3.3V)

Processor: 2x ARM Cortex A9 1GHz; 1GB DDR3

Digital inputs: 16x Electrical (3.3V)

FPGAs: Xilinx Kintex 7 125K; (user programmable)

Fault inputs: 16x Electrical (1.8V); 1x Electrical interlock

Analog inputs: 8x 16bits @2Msps

Incremental decoder inputs: 4x 3-pins (A,B,Z) (shared with GPI inputs)

PWM outputs: 16x Electrical (1.8V); 16x Electrical (3.3V)

Communication: 1x USB 2.0 (computer); 1x Ethernet 1Gbps (RJ45); 3x SFP+ 5Gbps; 1x CAN; + user high-speed I/Os

User High-speed I/Os: 36x Electrical (3.3V)

The B-Board PRO is a small piggy-back control module meant to be assembled within a larger converter control system. It embeds the essential and application-independent part of a power converter controller and can be easily mounted on top of a system-specific carrier board.

The inverter control module is guaranteed to work exactly the same way as the B-Box RCP, with the exact same performance. In fact, the very same bitfile can be used on both devices.

Despite its numerous I/Os, the control module measures only 86×124 mm. This is small enough to be assembled in most industrial systems. It also fits within a headroom of 22mm only!

The embeddable control module is exactly as powerful as the B-Box RCP. Indeed, with its dual-core 1GHz processor, it features outstanding performance, especially for an embedded controller.

Everything you may ever need to control advanced power inverters!

Our inverter control module is ready for the most demanding needs and has been specially designed with low- to mid-volume, complex applications.

With its high number of digital I/Os, there’s plenty of extension margin. The application scope is thus mostly defined by the available analog inputs.

Ideal for distributed control applications!When needed, hierarchized or distributed control systems can also be implemented. This allows either building larger control systems or interconnecting several programmable controllers together.

Communication can be implemented easily over Ethernet, CAN, or our proprietary low-latency protocol running over optical fiber links (SFP).

The B-Board PRO inverter control board brings most of the benefits of a rapid prototyping system directly into industrial applications. When compared to the B-Box RCP, it offers the same development environments, exact same performance, and same remote access capabilities.

The converter controller can be programmed using C/C++ code, or directly from simulation software, such as Simulink and PLECS. Thanks to a fully automated code generation toolchain, just one single click is all it needs to fully program the device!

The provided blocksets also embed simulation models so that the system can be accurately simulated and tuned before run-time is generated.

Absolutely no expertise in FPGA-based development is needed to work with this industrial control module. It operates readily with a highly flexible and highly configurable FPGA firmware.

Nevertheless, for the advanced users who require to alter the FPGA code, the B-Board PRO allows doing so. In this case, dedicated areas are provided, with straightforward integration within the existing DSP software kernel.

The converter control module uses a dual-core processor. One core is dedicated to the execution of the closed-loop control tasks (bare metal, dedicated kernel), the other one to the system supervision and monitoring (linux). Most low-level tasks are also shifted in FPGA.

This results in the full dedication of a fast floating-point processor core to real-time control tasks, with best-in-class performance, ranging up to 400kHz control frequencies in closed-loop operation.

In addition to being 100% compatible with the prototyping controller, the inverter control board benefits from the same software environment and tools. It, therefore, facilitates debugging and testing activities in the same way!

Overall, integration efforts are often limited to mechanical aspects, which are specific to the application anyway. All the rest is in direct continuity with previous work done with the B-Box RCP.