- Home

- Companies

- Taset Inc.

- Products

- Taset - Jet Digester & Biogas Reactor

Taset - Jet Digester & Biogas Reactor

Configuration technology of method. Chopper Pump: chops and homogenize solids in the digester using a chopper pump. Two-phase jet nozzle: Full mixing of the digester by strong injection using the two-phase jet nozzle.

Effect of process

Since viscosity is lowered due to homogenization and complete agitation by the pulverization of solids in the digester, the production of biogas increases, and loss of production of biogas is secured even during maintenance such as pumps.

Cost Reduction

The system is installed outside the digester without a separate rotating facility inside the digester, the installation of hatches, platforms, ladders, etc. is not required. System supply costs can be reduced as structural support is not required, which should have been provided by the mixer installed inside the digester.

Sanitation environment and safety effect

Health environment and safety for operators are ensured since working at a high place for opening the upper part of the digester or inside the digester is not required.

- Rotating and stirring equipment inside the digester are not required.

- Maintenance and service are available without needing to empty the digester or open the top cover of the digester.

- No loss of gas production when maintaining the pump

- Working at a high altitude at the top of the digester and inside the digester is not required, ensuring a working environment and safety

- Biogas production is increased by increasing the digestion efficiency through pulverization, homogenization, and complete agitation of solids.

- Strong agitation inside the digester with chopper pump and 2~3 spraying jet nozzles

- No scum stack is formed on the top of the digester due to the gas stirring pattern generated inside the digester.

- Nearly no temperature difference between the upper and lower parts of the digester.

- Easy replacement and improvement to improve the efficiency of existing digesters are available.

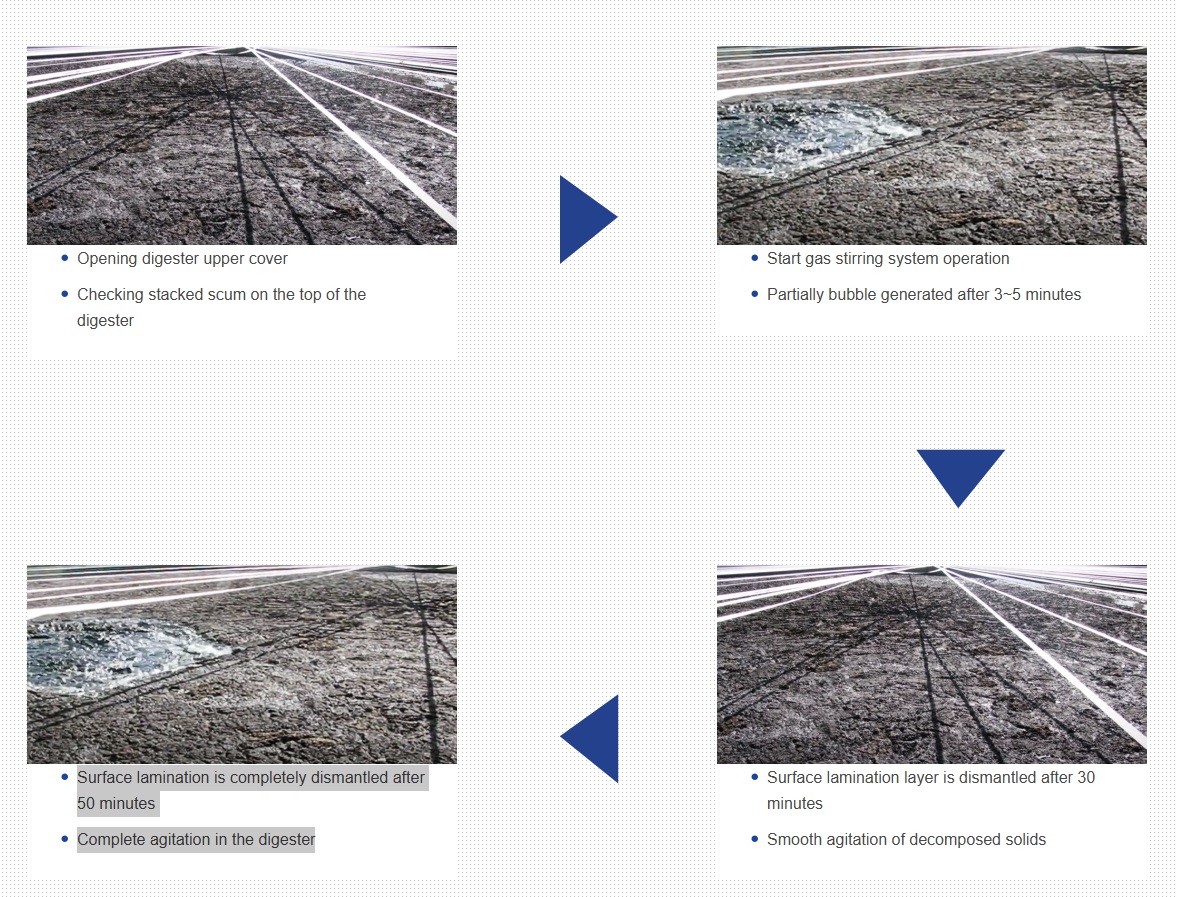

Step 1

Health environment and safety for operators are ensured since working at a high place for opening the upper part of the digester or inside the digester is not required.

Step 2

The inhalation of biogas in the upper part of the digester is stopped, and agitation is processed while being strongly sprayed into the digester through the jet nozzle installed in the lower part of the digester.

Step 3

It is strongly sprayed into the digester through the jet nozzle installed on the upper part of the digester and the agitation is processed so that scum is not formed inside the digester.