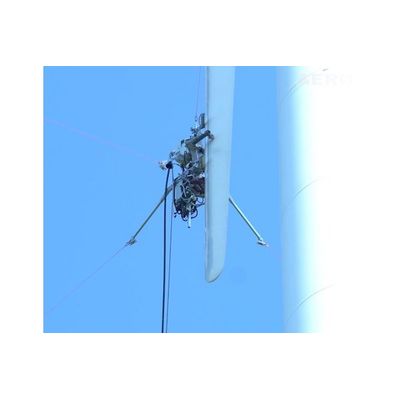

Robotic platform with a rich family of services

The unique proprietary system brings high-quality robotic services enabling our wind turbine technicians to perform repairs.

Surface preparation

The blade surface is prepared for a perfect repair service. Old protective tape is removed, the robot performs cleaning, sanding and applies the promoter solution.

Filler application

Eroded surface is filled with certified filling solution and is evenly applied to the blade, thanks to a careful smoothing technique.

Sanding

After filler application, the blade surface is sanded repeatedly to ensure perfectly smooth surface. Airflow is renewed to a near perfect level.

Leading Edge Protection

The final stage is applying the protection coating to safeguard the blade surface from erosion for the next years to come.

More effective repairs in cooperation with humans

We do not take the job away - to offer a full scope of blade repair, Aerones cooperates with technicians. Robots perform leading edge erosion repairs and technicians provide support in monitoring and repairing fiberglass, cracks, and delamination. Robots will allow the wind industry to turn towards fast and efficient preventive maintenance and forget about "long downtime," corrective and expensive repairs!

From corrective to preventive maintenance

Erosion must be prevented regularly before it evolves and damages the composite materials and lead to structural damage completely halting the wind turbine.