Rongsheng Group

- Home

- Companies

- Rongsheng Group

- Products

- Rongsheng - Magnesia Carbon Brick for ...

Rongsheng - Magnesia Carbon Brick for Kilns

FromRongsheng Group

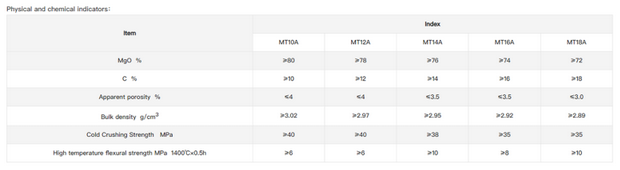

Magnesia carbon brick is made of magnesia and carbon materials, and various non-oxide additives are added. Magnesia carbon brick is a kind of basic refractory material. As a composite refractory material, magnesia carbon brick effectively utilizes the slag erosion resistance of magnesia and the high thermal conductivity and low expansion of carbon.

Most popular related searches

carbonization

refractory brick

industrial furnace

electric power

electrical power

industrial power

furnace

- Brand: Rongsheng

- Function: Fire-resistant and high-temperature resistant

- Origin: Zhengzhou, China

- Product advantages: Low impurity content, precise size, good heat preservation effect.

- Application industries: Iron and steel industry, electric power industry, non-ferrous metal industry

- Samples: Samples are available Customization: Send drawings and provide customized services for magnesia carbon bricks

- Factory: Has been established for 20 years

- Scale: 80,000 tons of refractory bricks and 50,000 tons of unshaped refractory materials can be produced annually

- Support to visit the factory, Send an offer ASAP!

- High-temperature resistance: Mag carbon bricks have a high softening point, usually at 1900-2000°C, which can meet the high-temperature requirements of most industrial production

- High slag resistance: Magnesia carbon bricks can react with various metal slags at high temperatures to form a protective layer, cutting off the further reaction between slag and bricks, so they have high resistance to slag erosion, especially suitable for slag content Large and complex occasions.

- Low water ingress rate: Magnesia carbon bricks have high density, almost no water absorption, good water resistance, and will not be damaged by water.

- Thermal shock resistance: The softening point of magnesia carbon bricks can reach above 1900°C, and the service temperature range is very wide, which can be used in most industrial furnaces.

- Good high-temperature resistance.

- Strong slag resistance.

- Good thermal shock resistance.

- Low creep at high temperatures.

- Low thermal expansion rate, not easy to deform.

- Not easy to peel off.