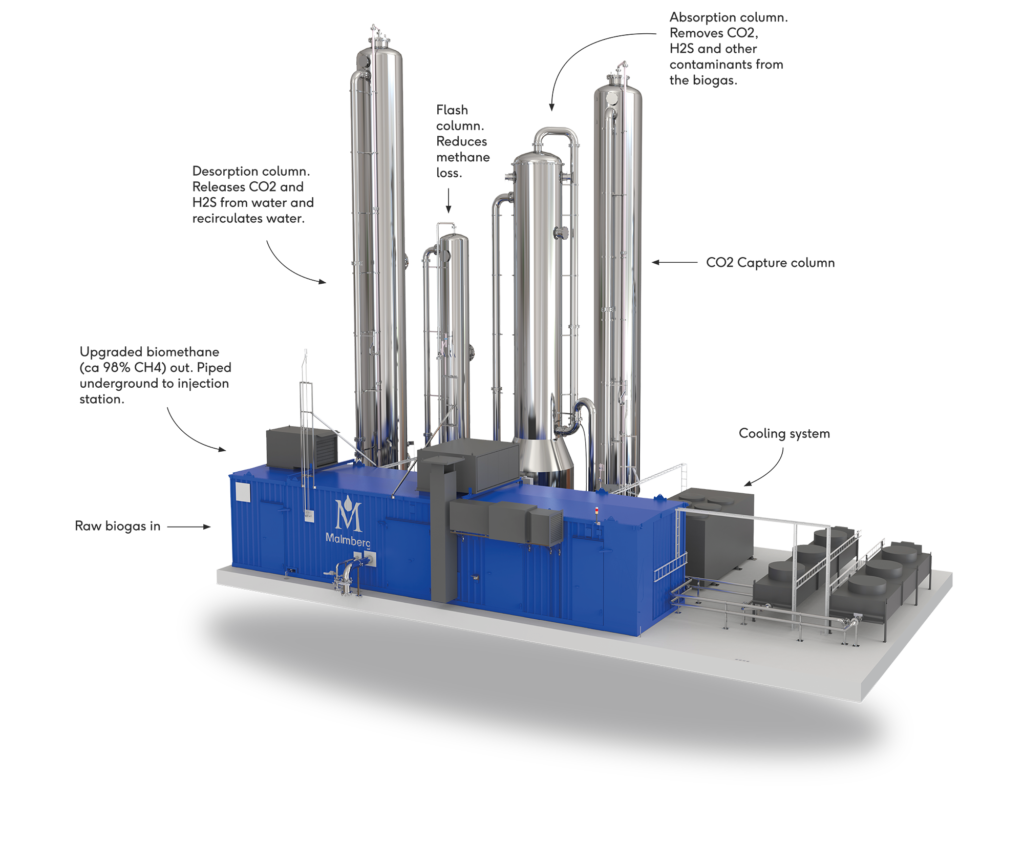

Malmberg Compact - Biogas Process System

With over 20 years of experience and groundbreaking technology in biogas upgrading, we are proud to offer a solution that takes your operation to the next level of sustainability. By leveraging our expertise and deep understanding of the biogas process, you can produce clean and renewable biomethane with a Malmberg COMPACT™ system. We offer a range of standard sizes based on the customer’s raw gas capacities. We also provide customized solutions tailored to your specific needs.

- Recovery rate >99%

- Availability >98%

- Methane slipp <1%

- Minimal water consumption

- Handles all variants of feedstock

- Low energy consumption

- Stainless steel columns

- Prefabricated solution

- 24/7 remote access

One of our key features is our commitment to reducing carbon dioxide emissions by offering CO2 capture at our upgrading facilities. With our advanced technology, we can capture and separate carbon dioxide from the produced biogas, resulting in a cleaner and more sustainable energy source.

With innovative membrane technology from Malmberg X Axiom, biogas can be easily upgraded and converted into clean, usable CO2. Through our successful pilot project and collaboration with Axiom, we have developed an efficient method for processing biogas. The purified CO2 produced can be used in various carbon capture systems or industrial processes, contributing to increased environmental sustainability and resource efficiency. With our solutions, you get a reliable and effective method to maximize the benefits of your biogas production and support your sustainability goals.

Through our extensive experience and network of partners, we offer a comprehensive solution for converting biogas into liquefied biomethane. Liquefaction allows for easy transport and storage of biomethane, opening opportunities for use in transportation, industry, and other sectors.