Meper - Model MP70D -Double Station Multi-Layer Extrusion Blow Molding Making Machine for Lubricating Oil Bottls

MP70D is specifically designed for making bottles from 50ml up to maximum 5L. It is hydraulic driven with accrate eletrical control system. MP70D has double stations to increase the production efficiency. Also, it has variety of choice of die heads. With more than 10 years of success in the market, MP70D is updated to be one of the most reliable and popular model in the world

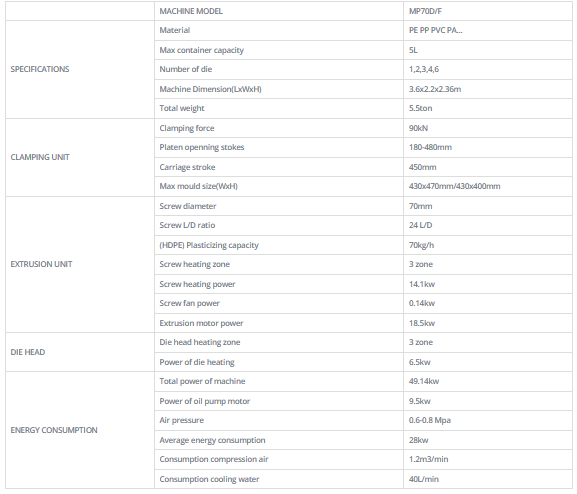

- Brand: MEPER

- Model: MP70D

- Material: PP PE PVC PA......

- MAX container capacity: 5L

- Number of die: 1,2,3,4 Set

- Machine Dimension: 3.6x2.2x2.36m

- Total weight: 5.5 Ton

Introduction

D series machine is standard type machine with double station tie bar structure, The clamping structure is three or four tie bars direct locking structure with automatic lubrication system. The structure is simple and stable and it is convenient for plastics waste collection.

MP70D is specifically designed for making bottles from 50ml up to maximum 5L. It is hydraulic driven with accrate eletrical control system. MP70D has double stations to increase the production efficiency. Also, it has variety of choice of die heads. With more than 10 years of success in the market, MP70D is updated to be one of the most reliable and popular model in the world.

Extrusion Die Head: Highly Experienced Multi-cavity and Multi-layer Technology

- Adopting with latest die head design, MEPER focuses on providing high quality and high precision self-manufactured extrusion die heads for customers.

- Control System: Highly Optimized User-friendly Control Technology

- All Meper Machines is Equipped in Standard with Easy Operational Techmation Control System or Optional with B&r Control System. Moog Parison Control is Also Optional Based on Different Requirements.

Clamping System: Highly Developed Tie Barless Design

- MP-D Tie-bar series employs direct-acting clamping system transferring the forces directly to the middle of the back platen and converting the same force to the front by tie bars and alignment rod. This tie-bar design offers quick mould change and convenient scrap collection.

Energy Saving: High Standard of Energy Saving System

- MP55D is equipped with high standard of energy saving driving systems. All extrusion and hyraulic motors are in IE3/4 energy level. Also, servo energy saving feature can be easily applied.