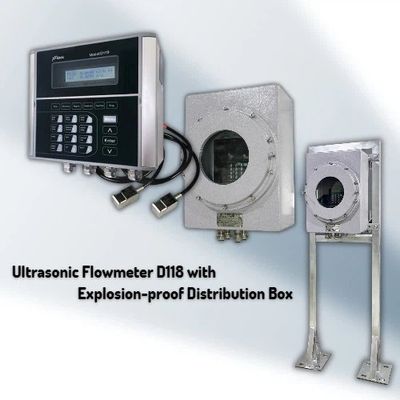

Model D118 -Flowmeter With Explosion-proof Distribution Box for Petrochemical

D118 Wall Mount Type Ultrasonic Flow Meter. HRMD Series Explosion-proof Distribution Boxes. For Petrochemical, Liquid Blending Systems, Single pot granulator, Oil and derivatives, Explosion-proof Distribution Box and D118 ultrasonic flowmeter are two distinct components used in different aspects of industrial settings. Let`s understand each of them separately: Explosion-proof Distribution Box: An Explosion-proof Distribution Box, also known as an Explosion-proof Junction Box or Enclosure, is designed to contain electrical equipment and wiring in potentially hazardous environments. These environments may have flammable gases, vapors, or dust particles that could ignite and cause an explosion. The distribution box is constructed with materials and engineering techniques to prevent the ignition of surrounding flammable substances. It ensures that any sparks, heat, or electrical arcs generated within the box are contained, thus minimizing the risk of an explosion.

- Hazardous Environment Protection

- Component Protection

- Long-Term Reliability

- Safety Compliance

- Operator Safety

D118 Ultrasonic Flowmeter: An ultrasonic flowmeter is a device used to measure the flow rate of a fluid by utilizing ultrasonic waves. It operates on the principle of measuring the time it takes for ultrasonic signals to travel through a medium. The flowmeter consists of sensors that emit and receive ultrasonic signals across the flow path. By analyzing the time difference between upstream and downstream signals, the flowmeter can calculate the velocity and volume flow rate of the fluid.

Regarding the relationship between an Explosion-proof Distribution Box and D118 ultrasonic flowmeter, it primarily lies in their application within hazardous environments. In certain industrial settings, where flammable substances are present, it is crucial to ensure that all electrical equipment, including the ultrasonic flowmeter, is appropriately protected. Therefore, an Explosion-proof Distribution Box can be used to enclose and safeguard the electrical connections and components of an ultrasonic flowmeter, ensuring it operates safely in such hazardous locations.

By placing the ultrasonic flowmeter within an Explosion-proof Distribution Box, the risk of ignition or explosion due to electrical faults or sparks is significantly reduced. This protective measure ensures compliance with safety regulations and mitigates potential hazards in environments where explosive atmospheres are a concern.

Digital Correlation Transit Time Flow meter

Installation method: Wall mount

2G SD card high memory data logging, maximum memorize 512 days data.

Flow Range: 0.03 ~ ±40ft/s (0.01~ ±12 m/s)

Accuracy: ±0.5% of measured value

Repeatability: 0.15%

Pipe Size Range: 1″~200″(25mm ~ 5000mm)

Keyboard:16 (4×4) touch keys

Display: 20*2, alphanumeric, backlit LCD

Power supply: 90-250VAC, 48-63 Hz or 10-36V DC

Transmitter enclosure: IP65, die-cast aluminum machined enclosure

Output: 4~20mADC, OCT pulse output, relay output

Communication: RS-232 / RS-485 terminal Modbus Protocol

ATEx standard, aluminum alloy housing, surface spray RAL7040;

Width 350mm * Height 450mm * Thickness 280mm, excluding terminals:

Gran: DQM-I, non-armored, cable wiring, material SS304, 8-M20*1.5B;

Panel opening 160mm * 80mm glass window, internal instruments to be provided by the customer, self-installation (including internal bracket). Internal with a positive installation plate: covered with aluminum-zinc plate, 290mm * 450mm;

The space size meets the requirement of "240mm * 290mm * 160mm".

Ex db lIB+H2 T6/T5/T4* Gb

Ex db [ib] lIB+H2 T6/T5/T4* Gb

Ex tb lIIC T80°C/T95°C/T130°C* Db

IP66

-60°C ≤ Ta ≤ +60C(+40°C)*

* The temperature class, assigned maximum surface temperature and maxi

See Conditions of Manufacture in the Annex.