Model PET -Stretch Blow Moulding

Ever since the remarkable breakthrough of stretch blow moulding technology for production of PET containers, Seitz is providing cutting edge solutions for this industry. Years of dedicated technical development and experience combined with constant pursuit of excellence have placed Seitz at the leading position within the field of valve technology for stretch blow moulding machines. Our products deliver functionality in an easy, simple and flexible way accounting customer’s need for integration and reliability. Seitz “nothing but the best” attitude justifies why manufacturers around the world trust our products.

- Compensation and Cooling Valves

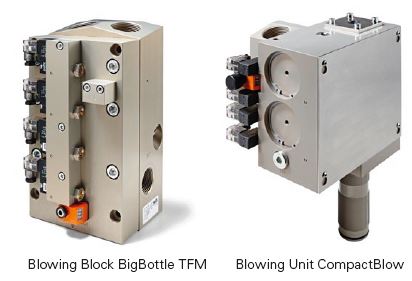

- Blowing Blocks

- Blowing Units (Cylinder-Valve combination)

- Integrated Blowing Stations (Cylinder-Valve combination including Electrical Stretching Unit)

You can count on our Performance

Seitz stretch blow moulding valve solutions guarantee best-in-class performance for:

- Minimal dead volume

- Fast, accurate and repeatable valve switching times

- Maintenance friendly design

Optimal energy efficiency, high output and long maintenance intervals of the Blowing Station keep the TCO value of your machine as low as possible.

Experts who speak your Language

Our extensive and to the point expertise guarantees that the delivered high-end valve solutions will be tailored to your needs and they will maximize the performance of your machines. Furthermore, the inclusion of high-precision measuring technology and Wi-Fi offers a comprehensive tool to monitor and analyze the blowing process as well as to identify further optimization potentials.

Our modern technical infrastructure allows us not only to employ the latest simulation tools for development but also to reproduce in our laboratory the entire customer defined stretch blow moulding process. Therefore both technical and life span specification can be validated prior to product delivery. These features make Seitz your perfect development partner.