- Home

- Companies

- Zhengzhou Kerui Industrial Development ...

- Products

- Kerui - Mullite Insulation Brick

Kerui - Mullite Insulation Brick

Mullite insulation brick is insulation bricks primarily composed of aluminum oxide. They have good features. Kerui is the experienced manufacturer and supplier. We offer quantity certificates and insulation solutions to partners. More than 1000 partners from 50+ countries have adopted our products and solutions.

- Al2O3: ≥38-73%;

- Fe2O3: 0.55-1.2%;

- Bulk Density: 0.6-1.2g/cm³;

- Classification Temperature: 1260-1550?;

- Cold Crushing Strength: 3.0-4.5MPa;

- Size: 230*114*65mm (standard) and others;

- Delivery: 15-30 working days;

Mullite bricks are insulating bricks made primarily from mullite. Mullite is a mineral compound composed mainly of aluminum oxide and silicon dioxide. Small amounts of glass phase, cristobalite, and corundum are also part of its composition. This brick has a unique crystal structure, with aluminum oxide content ranging between 70-78%. It has low impurity content. So, it is a popular choice for raw materials in high-temperature industries.

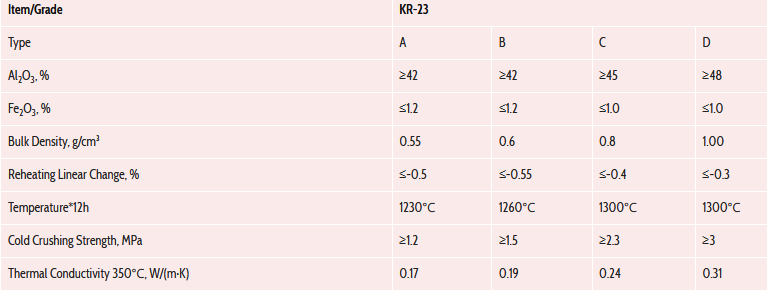

After firing, the aluminum oxide content in mullite insulation bricks ranges from 42-72%. Its main components include mullite, additives, and others. Mullite insulation bricks exhibit excellent properties such as resistance to acid and alkali erosion, low thermal conductivity, uniform expansion, and so on. Additionally, these insulation bricks have good workability and plasticity. These features enhance convenience in transportation and construction processes.

High Refractoriness

The mullite insulating brick has a high refractoriness, reaching up to 1790 degrees Celsius. The load softening temperature is approximately 1600-1700 degrees Celsius. It is suitable for use in high-temperature environments and has a long service life.

Low Creep at High Temperatures

Mullite insulating bricks have high strength, low creep at high temperatures, and good thermal shock stability. They exhibit strong volume stability at high temperatures. And they can maintain a stable structure during rapid temperature changes.

Low Impurity Content

Mullite insulating bricks have high purity and low impurity content. This factor results in stable performance and durability. Many customers choose this kind of bricks in high-temperature industry.

Low Thermal Fusion

It has low thermal fusion, low thermal conductivity, low density volume, and light weight. The thermal conductivity of mullite brick is 0.19-0.43. Low thermal conductivity effectively insulates heat flow, helps maintain temperature in furnaces, and reduces heat loss. Thereby, it helps improve energy efficiency for businesses. It is suitable for areas with specific requirements for thermal efficiency, such as furnaces.

Strong Chemical Resistance

This type of brick has extremely strong resistance to acid and alkali erosion. It will not corrode or damage when used in acidic or alkaline working environments. It can maintain equipment stability and reduce equipment wear and tear. This is crucial for the high-temperature industry. This feature makes it suitable for long-term use in corrosive environments.

Environmentally Friendly

Mullite bricks and bubble alumina refractory bricks are made from natural materials. And the production process meets environmental requirements. Additionally, factory equipment is equipped with dust removal systems.

Steel Smelting Industry

The mullite insulation brick in the steel metallurgy industry is mainly used to reduce heat loss in high-temperature environments. It is commonly used in the construction of hot blast stoves, blast furnaces, annealing furnaces, resistance furnaces, aluminum reduction cells, and insulation furnaces.

Building Materials Industry

In the building materials industry, there is a high demand for mullite insulation bricks to maintain temperature and corrosion resistance. They are used in glass melting furnaces, glass heat storage chambers, cement kilns, rotary kilns, bell kilns, ceramic sintering kilns, high-temperature ceramic furnaces, and so on.

Petrochemical Industry

In the petrochemical industry, mullite bricks improve energy efficiency. They are used in petroleum fractionation furnaces, ethylene pyrolysis furnaces, pyrolysis furnaces, conversion furnaces, heating equipment, petrochemical combustion pits, and other equipment.

Power Generation Industry

In the power generation industry, mullite insulation bricks are widely used in boilers, furnaces, incinerators, and so on. They enhance the insulation and efficiency of power generation equipment. And they improve the overall performance of the industry’s equipment.