- Home

- Companies

- Tenmat ltd

- Products

- NITRASIL - Silicon Nitride

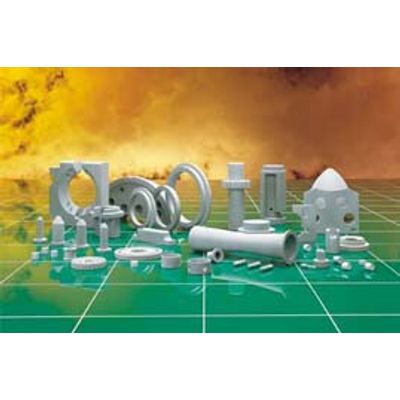

NITRASIL - Silicon Nitride

NITRASIL is an engineering ceramic with superb inert properties that allow applications in numerous high temperature and non ferrous molten metal environments.

NITRASIL is able to be machined into complex component shapes and major application fields include induction heating, brazing fixtures, high temperature analytical equipment and non ferrous molten metal handling, including metal particle atomisation.

The material is lightweight, inert and strong. It has a low expansion coefficient and good thermal shock and thermal cycling resistance.

Excellent resistance to oxidation is achieved up to 1150°C.

NITRASIL is resistant to almost all chemicals and non ferrous molten metals.

NITRASIL is not affected by induction currents.

NITRASIL is both an electrical and thermal insulator.

Aluminium Industry

Aluminium primary production and secondary processing plants benefit from the use of TENMAT`s extensive range of products wherever heat must be contained, electrical energy controlled or wear resisted. TENMAT products offer cost effective solutions to improve energy utilisation, reduce weight and operating costs and increase life cycle operation.

- SINDANYO L23 is used in the potroom in strip form between pot covers and cathode frames and in pad or plate forms between the anode support, the control gear and the super structure.

- SINDANYO H91 is an ideal material for crust breaker discs, busbar and primary frame insulation and door frames.

- ARCLEX provides the necessary electrical insulation of the cathode frame on its concrete base and to insulate busbars from the steel retaining and cathode frames.

- FIREFLY FF700 MILLBOARD is a popular choice for many sealing requirements including syphon tube gaskets in molten metal transfer equipment.

- FIREFLY FF700 MILLBOARD provides the insulating layer between the crucible and its hot face refractory lining, reducing heat losses thereby maintaining melt temperature longer. It is also used underneath the pots. FF700 possesses the necessary strength to be used as a permanent former when casting concrete.

- Inside the pot FIREFLY FF700 MILLBOARD shields the anodes in order to exclude alumina whilst gas heating takes place during start up. Once operating temperature is reached the millboard becomes a sacrificial component in the pot.

- RF1000 grade products are used as the insulation in crucibles, transport ladles and launder systems ensuring cost effective maintenance of liquid metal temperature for long periods of time.

- CS1150 pouring nozzles have replaced conventional calcium silicate and cast iron tubes for flow control of liquid aluminium.

- NITRASIL greatly extends the working life of graphite shafts used in rotary degassing equipment.

- NITRASIL is hard and wear resistant. Its use as seats and pistons in valving operations ensures trouble free performance.

- REFRAVER is used to resist attacks by fluorine in electrical and thermal environments.

Molten Metal Processing

Molten metal processing plants worldwide benefit from the use of TENMAT`s extensive range of high temperature materials.

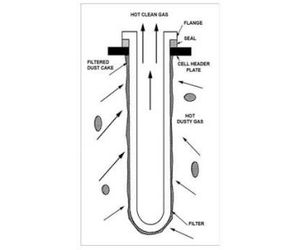

TENMAT manufactures a wide variety of materials for thermal insulation, electrical insulation, gasketing and molten metal handling. Typical applications for TENMAT high temperature materials include pouring nozzles, tap out cones, molten metal transfer pump components, crust breakers, gaskets and many others.

SINDANYO, TENMAT`s high temperature cement boards are the ideal materials for crust breaker discs, busbar and primary frame insulation and door frames.

FIREFLY Millboard is a popular choice for many sealing requirements including syphon tube gaskets in molten metal transfer equipment, centrifugal casting, ladle gaskets and plate rings.

CS1150, one TENMAT`s top performing Refractory Products, is used as pouring nozzles and replaced conventional calcium silicate and cast iron tubes for flow control of liquid aluminium.

NITRASIL, an engineering ceramic, exhibits high mechanical strength and exceptional wear resistance capabilities. The material is primarily used for applications in contact with molten metals like rotary degassing equipment, molten aluminium handling, zinc atomisation systems, non ferrous metal handling and others.

Whether it is in the operation or maintenance of process equipment TENMAT`s products offer cost effective solutions to improve energy utilisation, decrease operating costs, reduce weight, and increase life cycle operation.