- Home

- Companies

- Noardling B.V.

- Products

- Noardling Landustrie - Hydropower Screw ...

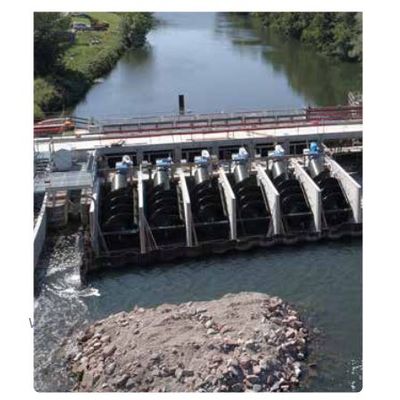

Noardling Landustrie - Hydropower Screw Pumps

Flowing water is a relentless, never ending source of power for pure, clean renewable energy. All you need to benefit from this natural resource is a Landustrie hydropower screw system.

We design, build and install highly efficient, cost effective and environmentally beneficial hydropower turbine system solutions which are specifically designed for relatively low head, high flow river courses.

An environmental friendly solution can only be called a sustainable solution if it is economically viable. We help you achieve a truly sustainable project by combining years of hydropower engineering experience with professional project guidance throughout the process. With our experts providing all roles from initial site investigation, through engineering/design to manufacturing and installation, your costs are kept low; therefore, ensuring your project is truly an environmentally and financially sustainable solution.

The checklist needed for a hydropower screw is limited:

Is there flow and is there head?

The most straight forward projects will answer yes on both questions. However, less obvious situations might be well suitable for a hydropower screw. Think about:

- A complete new site, where a head can be created in the river or canal.

- At an existing dam or weir, the hydropower screw can simply be added.

- A dysfunctional hydropower plant is also suitable to be replaced by the hydropower screw.

- Outlets of sewage treatment or hydropower plants.

- Existing hydropower plant’s overspill or fish by-wash

The principle of the Landustrie hydropower screw dates back to 300 B.C., when Archimedes invented the screw pump. In the last decade Landustrie altered the design, making the screw pump suitable for hydropower: the Landustrie hydropower screw.

By placing the screw inclined in the flow direction of a river, the water stream is directed into the screw. When water enters the screw, the combination of potential and kinetic energy of the water forces the screw to rotate. The higher the potential or kinetic energy, hence a higher head or flow, the higher the output power.

The relatively slow rotational motion of the screw is transferred via a gearbox to the generator. Here the rotational energy is converted into electrical power, ready to use or to sell to the grid.