- Home

- Companies

- Ionox Odor Elimination Systems - UAS ...

- Products

- Ionox - Non-Thermal Plasma (NTP) ...

Ionox - Non-Thermal Plasma (NTP) Technology

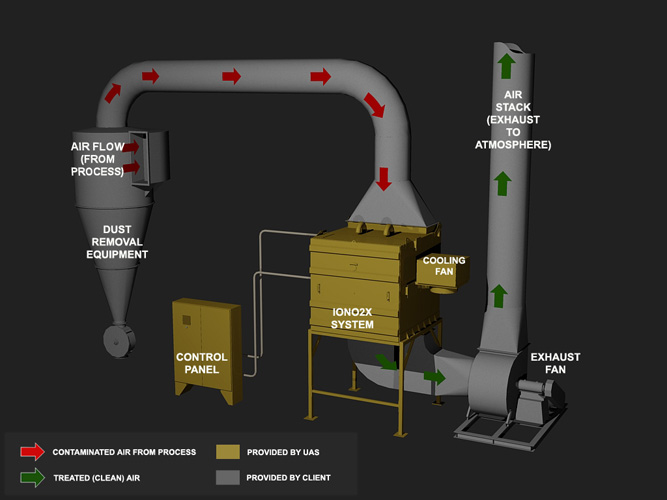

Ionox Non-Thermal Plasma (NTP) technology utilizes high voltage electrodes connected to a rapidly pulsing, high voltage power supply. The configuration of the electrodes creates a rapidly reversing, high intensity electrical flux within the electrode air gap. As the contaminated air stream passes through the electrode gap, the high intensity electric flux density fractures the volatile organic compound (VOC) molecules within the air stream, and strips and heats very low mass electrons to extremely high temperatures. Large volumes of micro discharge streamers, essentially tiny lightning bolts which produce a violet glow, are created. These streamers collide with diatomic oxygen and water vapor molecules in the contaminated air stream, forming highly reactive oxidative radicals, known as Reactive Oxygen Species (ROS) and Hydroxyl Radicals (•OH). This extremely reactive mixture of ionized gas and very high temperature electrons is known as Non-Thermal Plasma (NTP).

The Ionox Odor Elimination Systems is a patented, proven, "True NTP" technology that has been developed, tested, and in production for over 20 years.

Within the non-thermal plasma inside the Ionox System, the ROS, •OH, and free electrons instantaneously react with the fractured VOC molecules to produce mainly water vapor and carbon dioxide. The key advantage of utilizing VOC oxidation to eliminate odor is that it allows oxidation reactions that would otherwise only occur at high temperatures of >1,350° Fahrenheit (>730° Celsius) to occur rapidly, with little measurable heat rise. NTP oxidation technology is highly energy efficient, as there is little heat rise of the treated air stream.

Ionox Odor Elimination Systems do not use plasma injection. On the contrary, Ionox Systems are “true” implementations of Non-Thermal Plasma technology. Free high temperature electrons, ROS, and •OH have a very short half-life and cannot be injected in reactively significant volumes, even over very short distances. First used in the late 1800s, ozone injection is a very old approach to odor control and has been shown to achieve odor reduction of 25-35% at best. So-called “NTP Injectors” or “Plasma Injectors” can only inject long-lived lower oxidation potential radicals, such as ozone. These systems can best be described as “ambient air fed ozone injectors” and are designed to produce large volumes of concentrated ozone. Quite the opposite, Ionox Systems minimize the production of residual ozone. We believe that any system that injects ozone into an air stream and that does not pass 100% of the contaminated air stream through the electrode gap is not NTP technology.

- Provides Odor Elimination of over 90% *1

- Patented Non-Thermal Plasma (NTP) Technology

- Low Operating and Maintenance Costs

- Energy Efficient, Green Technology

- Only consumable is Electrical Power

- No Water, Chemicals, Natural Gas or other Fuel Consumption

- Typical Power Consumption Ranges from 0.8 to 1.6 Watts Per Cubic Feet Per Minute (CFM) *2

- Excellent Operational Reliability

- No Moving Parts

- Simple to Maintain and Operate

- Single-Unit Systems can treat up to 85,000 CFM *3

- Able to treat any volume of air with multiple systems

- Remote Program Updates & Troubleshooting available via Ethernet Connection

- 24 Hour Monitoring*

- Standard Siemens PLC & HMI included, Allen Bradley also available*

Ionox systems include a PLC based control system with a touch screen interface and a Plasma Generation Cell cabinet which contains all of the high voltage components. To ensure operator safety, all Ionox systems include a Category 2 electrical safety interlock switch and retained key interlock system to prevent the PGC cabinet from being opened unless the system power is turned off. We routinely do extensive field testing and use only high quality, reliable components. With simple routine maintenance, Ionox Odor Elimination Systems provide many years of trouble-free operation.

Ionox Odor Elimination Systems employ patented technology (US Patent no. 6,991,768, no. 7,767,167, and no. 8,475,723). By using hermetically-sealed high voltage electrodes, we prevent electrical arcing which is a common problem in other industrial-scale NTP systems.

*1Verifiable odor elimination percentage calculated by Detection Threshold (D/T) analysis of "after treatment" samples divided by the D/T of “before treatment” samples.

*2 0.47 to 0.94 watts per cubic metres per hour

*3 102,000 cubic metres per hour

Benefits

- Proven Odor Elimination

- Cost Effective

- Reliable

- Green Technology that does not use water or fuel and produces zero waste

- Animal & Fish Feed Manufacturing

- Pet Food Production

- Human Food Preparation

- Tobacco Processing

- Sewage Treatment Plants

- Other Nuisance Organic Odors