- Home

- Companies

- Aerzener Maschinenfabrik GmbH

- Products

- Aerzener - Model Series DS - Oil-Free ...

Aerzener - Model Series DS -Oil-Free Double-Stage Screw Compressor

The double-stage air compressors of the DS series compress absolutely oil-free in accordance with ISO 8573-1, class 0 and guarantee outstanding performance in almost all application areas at differential pressures between 5.5 and 10.5 bar. A compact plug-and-play solution for your processes - not just for sensitive scopes of application.

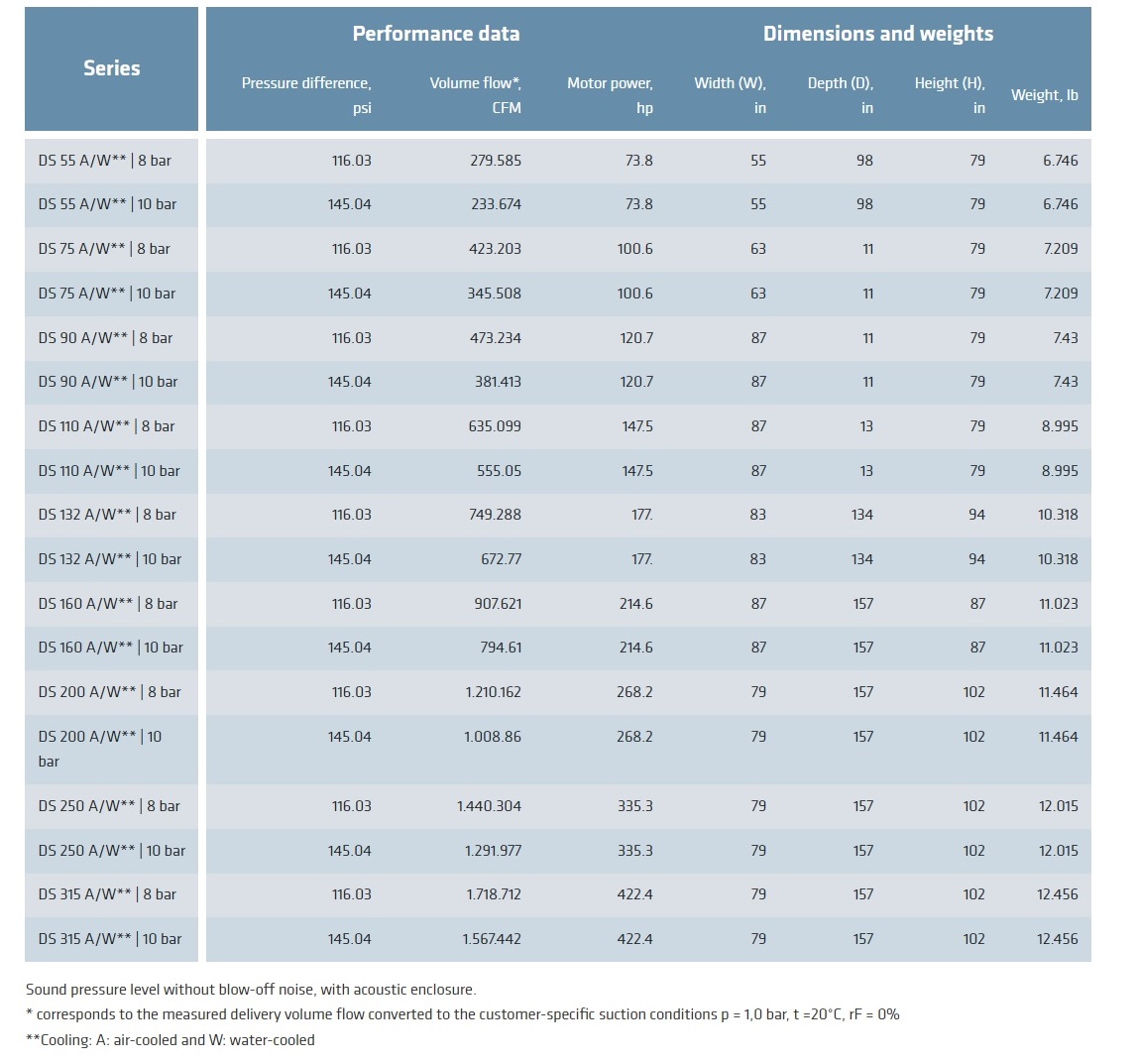

- Volume flow: 105.948 to 1.718.712 CFM

- Differential pressure (Δp): 79.77 to 152.29 psi

- Medium: Air, Neutral Gases

- Compression: Oil-free

The advantages of AERZEN Screw Compressor Series DS at a glance:

- Increased energy efficiency ensures additional savings of up to 12%

- Large volume flow control range thanks to reliable VFD technology

- Compact design leads to a very small footprint

- Maximum reliability and durability

- Safe use in extreme ambient conditions

- Plug & Play also in connection with outdoor installation and efficient IE5 motors

- Minimum sound pressure levels

- Reduced service costs thanks to extended maintenance intervals

- On-site service on compressor stages and on the package

As diverse as your applications

Compressed air is omnipresent in industry and has become indispensable in many applications - be it in chemical/ petrochemical process technology, electronics and semiconductor production and many other areas.

US Units: Yes

- Type of technology: Screw Compressors

- Design: Positive pressure

- Differential pressure (Δp) : 79.77 to 152.29 psi

- Volume flow: 105.948 to 1.718.712 CFM

- Medium: Air, Neutral Gases

- Compression: Oil-free

Exceptionally high energy efficiency

- Energy savings of up to 12 % compared to other compressor models

- Innovative bare-shaft compressors with new, highly efficient 4+6 rotor profiles in the low and high-pressure ranges

- Large turndown due to the use of VFD technology

- Optimised cooling by using cooling liquid (water or oil) in the double-walled bare-shaft stages

- Motors of energy efficiency class IE4 or IE5; in connection with an integrated VFD

- Direct drive by means of coupling and gear transmission for optimum drive efficiency

- Stainless steel rotors in both stages to prevent corrosion

High reliability and durability

- 100 % oil-free process air for sensitive applications, certified according to ISO 8573-1 Class 0

- PFAS-free process air generation

- Effective sealing concept for drive shaft and conveying chamber; minimisation of natural seal wear

- Extended fields of application: options for using the package in hot, dusty (desert installation) or extremely cold (polar regions) climates.

- Oil pressure lubrication for exceptional durability of the anti-friction bearings. Bearing life of up to 40,000 hours

- Permanent oil level check by means of an electrical oil pressure switch

- Reliable even in extreme climatic conditions thanks to the use of an oil cooler already included in the standard scope of supply

- Optional acoustic hood for outdoor installation. Enables the machine with integrated VFD to be used outdoors even under direct weather conditions

- Highly effective water separators ensure that condensate is drained as required

Reduced maintenance effort

- Operation and maintenance exclusively from the operating and rear side of the package

- Small footprint and side-by-side installation possible

- On-site service on the compressor stages and the package

- Effortless transport of the entire package using a pallet truck, fork lift truck or crane

- No maintenance required for drivetrain components

- Delivery of the package with a filled oil system enables quick commissioning

Smart oil system

- Mechanically driven oil pump on the drive shaft

- Highly efficient oil pump with reduced energy consumption

- Oil-lubricated anti-friction bearings with pressure lubrication achieve a service life of up to 40,000 hours

Permanently, intelligently reduced noise levels

- Minimum sound pressure levels thanks to intelligent noise reduction of the package

- Innovative pulsation reduction thanks to the use of Venturi nozzles downstream of both compressor stages