Akkaya

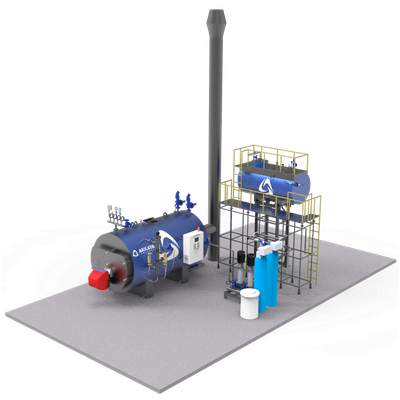

Akkaya - Model KBB Series -Oil/Gas Steam Boiler

FromAkkaya

Steam generation capacity: 300 kg/h - 3000 kg/h. Operating Pressure: 0.5-20 Bar. Fuel Type: Natural Gas, LPG, Diesel, Fuel Oil.

Most popular related searches

steam boiler

gas steam boiler

industry steam boiler

industrial steam boiler

steam superheater

boiler tube

steam generation

steam generator

industrial boiler

steam boiler generator

- Thanks to the design of the two pass, reverse flame type, fast and high quality steam production is achieved in a short time and with high efficiency.

- By the use of special designed turbulators and well selected firetube layout a compact design with sufficient efficiency has been reached.

- Due to its compact structure, it occupies minimum space in facilities.

- Design, production and commissioning can be carried out with economizer and steam superheater unit upon request.

- Provides safe and stable operation thanks to high quality safety equipment.

- Thanks to PLC controlled touch screen control panel, quick technical support can be obtained from anywhere in the world with easy operation and remote access from mobile devices.

- Shipped with long-lasting insulation that minimizes heat losses.

- The boiler is manufactured as corrugated and firebox corrugated according to operating pressure values. The strength of the boiler and its resistance to thermal stresses are thus increased.

- Production in accordance with EN12953 and PED2014 / 68 CE directive

- Welding control of our boilers is carried out with ULTRASONIC test within the scope specified in EN 12953 and according to EN 473

- Our welded productions are carried out by certified welders according to approved WPS and WPQRs. Automatic submerged arc welding, MIG-MAG and SMAW welding techniques are applied in accordance with the norms.

- They are manufactured by using high quality, certified boiler sheet and seamless boiler tubes in accordance with standard requirements.

- Akkaya 2 pass, reverse flame type steam boiler

- Burner

- 1 operating ,1 stand-by Grundfos brand feed water pump group with valves, filters and check valves

- PLC based touch screen and remote access control panel

- Isolated feed water tank including level controller, water inlet solenoid valve group and level indicator (steam heating on request)

- Safety valve

- Water softening system

- High quality electronic water level control systems

- Manometer and 3-way connection valve

- Reflex glass water level indicator

- Pressure switch Pressure transmitter

- Vacuum breaker and shut-off valve

- Steam temperature sensor

- Flue temperature sensor

- High quality steam exit valve, water inlet valve and check valve

- Surface blowdown valve

- Bottom blowdown valve and bottom blowdown shut-off valve

- Economizer, Recuperator, Thermic Deaerator, Automatic Bottom and Surface Blowdown Systems, (Optional)