Panda Pipe - Model SMLS -Seamless Pipe

An SMLS pipe is a pipe that has no welding seam. A seamless piping design can create several benefits such as increased strength and a smooth interior finish that is rust-resistant. Commercial, industrial, and residential customers will typically choose seamless pipes for their durability in various applications.

What is the Difference between SMLS Pipe and Seamed Pipe?

SMLS pipe is made using an extrusion method, which involves inflating a cylindrical metal tube through an opening in a die and then cutting it to lengths. The seamless pipe has no welded joint; thus, it has more strength and higher pressure capacity than equivalent size seamed pipes. The seamed pipe is made in a rolling process, which means that the welded joint is formed during production.

SMLS Pipe

- High in Price

- No welded joint

- Raw Material: solid round billets

- Outer Diameter: 1/8 inch to 26 inch

- Main Application: High-pressure

- Thickness Tolerance: instability

- Length Tolerance: instability

Seamed Pipe

- Relatively cheap in price

- a welded joint in its cross-section

- Raw Material: Steel Coils

- Outer Diameter: 2-3/8 inch to 24 inch

- Main Application: low/ medium pressure

- Thickness Tolerance: Relatively accurate

- Length Tolerance: Relatively accurate

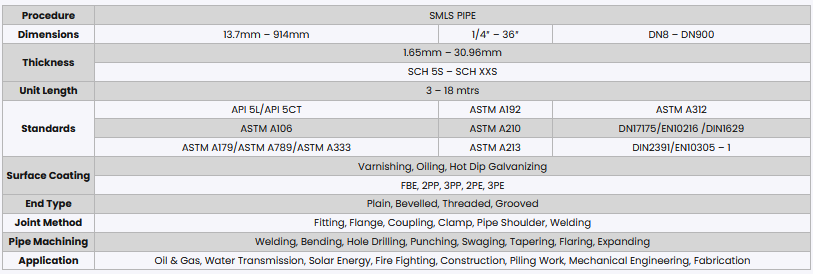

Our SMLS pipes are produced through a meticulous production procedure that ensures a seamless and uniform structure. These pipes are available in various dimensions and steel grades, each designed to meet different industry standards. The surface coatings applied enhance their durability and resistance to corrosion. The end types and joint methods can be customized to meet specific application requirements. These pipes are machined to perfection and find extensive applications in industries like chemical, petrochemical, and power generation.

Where SMLS Pipes are Used?

Due to superior mechanical strength and absence of seams, SMLS pipes are frequently used as water wall pipes, boiling water pipes, superheated steam pipes, superheated steam pipes for locomotive boilers, and arched brick pipes. Specifically throughout the nuclear, natural gas, petrochemical, shipbuilding, and boiler sectors.

- Oil & Gas

- Construction

- Water Transmission

- Piling Work

- Solar Energy

- Mechanical Engineering

- Fire Fighting

- Steel Fabrication