- Home

- Companies

- Caluwe, Inc.

- Products

- Caluwe - Model BioWIN XL - Pellet ...

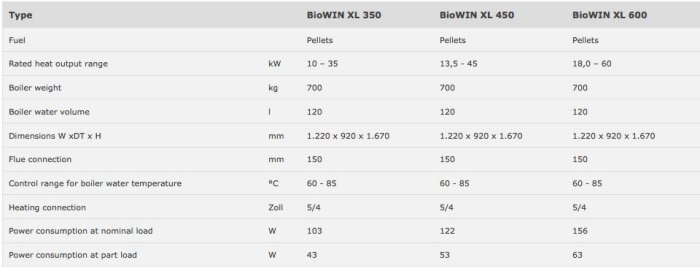

Caluwe - Model BioWIN XL -Pellet Boilers

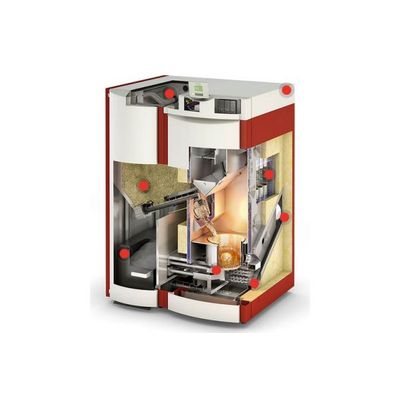

Well-designed to the smallest detail; Compact design; Space-saving floor space of only 1.12 m2. Heating surface cleaning; Long cleaning intervals thanks to fully-automatic heating surface cleaning. Ash box; Integrated ash box ensures long emptying intervals (1-3 times a year). Double ignition element; Zero-wear, long-life double ignition element ensures high operational safety and low maintenance costs.

- Sliding ash grate : Patented sliding ash grate running in the opposite direction ensures the complete removal of ash from the burner.

- Integral pellet fuel hopper : Large integral fuel hopper for about 135 kg of pellets enables long, uninterrupted burning phases.

- World first pellet feed : Unique, pneumatic pellet feed with 8 removal probes make inclined surfaces unnecessary in most cases.

- RLU adapter : Prepared for operation independent of room air as a standard.

To provide a follow-up supply of pellets, Windhager offers a fully automatic, patented feed system consisting of a changeover unit and up to eight removal probes.

Advantages:

- 8 probes can usually take the place of an inclined floor and therefore prevent large amounts of lost storage space

- Up to 8 removal points make the system incredibly reliable

- The storage room`s position Is independent of the heating room`s position

- Totally maintenance-free system

- No moving parts and no electrical cables necessary in the storage room

- Function check

Intelligent, flexible and safe

Larger buildings such as multi-dwelling homes or commercial properties can now be heated particularly efficiently and reliably with pellets: the BioWIN XL can be connected to two-unit, three-unit and four-unit cascade systems, thus providing for heating requirements ranging from 10 to 240 kW.

Intelligent

- Serial or simultaneous starting of the boiler

- Efficient operation thanks to continuous checking of how many and which boilers must be running

- Balanced utilisation of the boiler with run-time checking ensures a longer service life

- Highly efficient even at low performance thanks to the extensive depth of modulation

- Integration of external heat consumers (e.g. swimming pools and heating fans)

Safe

- Enhanced operational safety due to multi-boiler mode

- Service work possible with no heating interruption

- Also combinable with 1 peak load or emergency boiler

Flexible

- Combinable with different boiler power ratings

- Low space requirement due to intermediate frame (6.8 m2 for double, 9.6 m2 for triple and 12.4 m2 for quadruple)

- Optional 3 or 8 suction probes per boiler for a variety of storage rooms