- Home

- Companies

- Guangdong Pumbaaev Drive Technology ...

- Products

- Pumbaaev - Model Gen5 PML030 - ...

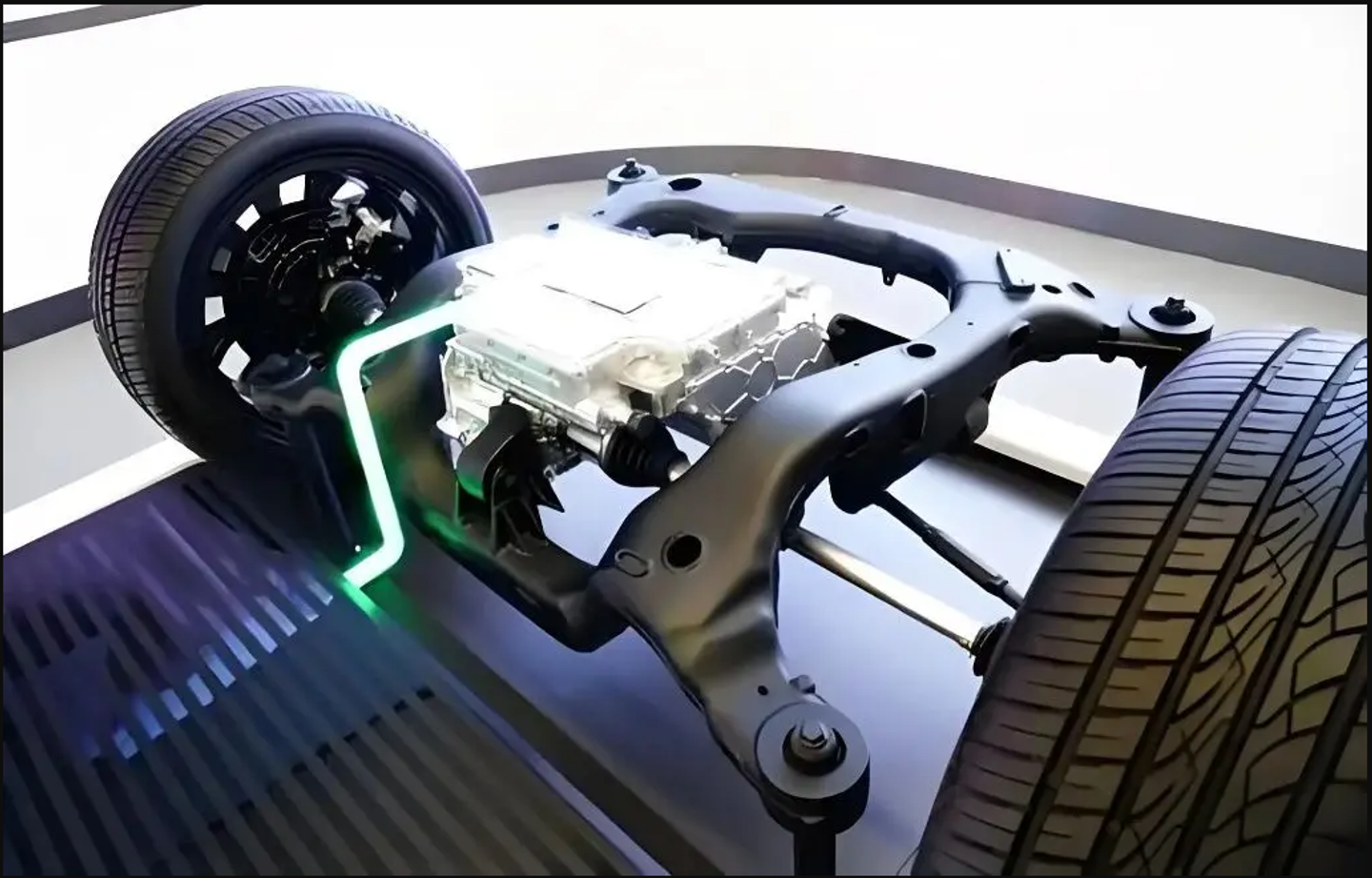

Pumbaaev - Model Gen5 PML030 -Permanent Magnet Synchronous Motors (PMSM ) for Electric Vehicle Drive

The winding form of the motor gradually transitions from round wire to flat wire, with high slot filling rate, short ends, high power density and strong heat dissipation capacity.

What is Permanent Magnet Synchronous Motor PMSM?

Permanent magnet synchronous motor is a type of AC synchronous motor whose magnetic field is excited by a permanent magnet that generates a sinusoidal reverse electromagnetic field. It contains the same rotor and stator as an induction motor, but the rotor uses permanent magnets to generate a magnetic field. As a result, there is no need to wrap magnetic field windings on the rotor. It is also known as a three-phase brushless permanent magnet sine wave motor.

Principle of permanent magnet synchronous motor

Compared with traditional motors, permanent magnet synchronous motors have high efficiency, brushless, fast speed, safety and high dynamic performance. It produces smooth torque and low noise, and is mainly used in high-speed applications such as robotics. It is a three-phase AC synchronous motor that operates synchronously with an external AC power source.

Instead of using windings, the rotor is fitted with permanent magnets to create a rotating magnetic field. With no DC power supply, these motors are very simple and inexpensive. It contains a stator mounted with 3 windings and a rotor mounted with permanent magnets to create magnetic field poles. Provide a three-phase input AC power to the stator and the operation will begin.

Permanent magnet synchronous motors work similarly to synchronous motors. It relies on a rotating magnetic field to generate an electromotive force at synchronous velocity. When the stator windings are energized by a three-phase power supply, a rotating magnetic field is generated between the air gaps.

Torque is generated when the rotor poles maintain a rotating magnetic field at a synchronous speed, and the rotor rotates continuously. Since these motors are not self-starting, it is necessary to provide a variable frequency power supply.

- Compact structure and simple control: high reliability, high power density, excellent NVH performance

- Cost-effective: light weight, simple structure

- High efficiency: high efficiency, motor efficiency up to 98%

- Model: PML030

- Cooling Method: Water cooling

- Peak Power: 60KW

- Rated Power: 30KW

- Peak Torque: 200N.m

- Peak Speed: 9000rpm

- Overall Dimensions: 326×260×300mm

- Applications: Car/Minivan/ truck

High voltage insulation design

The motor adopts new insulating materials and processes to meet the high switching frequency requirements of SiC controllers for increasingly high-speed motors

High-speed and heavy-duty insulated bearings

The motor design uses insulated bearings, which can meet the design requirements of 24000RPM/min; And it can effectively inhibit the generation of electrical corrosion of bearings

Oil-cooled motor

The motor adopts a high-speed oil-cooled structure, which effectively reduces the rated power after the volume is reduced, which not only improves the efficiency, but also improves the service life of the system

Excellent NVH performance

The motor rotor adopts a segmented inclined pole structure, which effectively optimizes the NVH of the motor system