- Home

- Companies

- KULR Technology Group, Inc.

- Products

- KULR - Model PCM - Phase Change ...

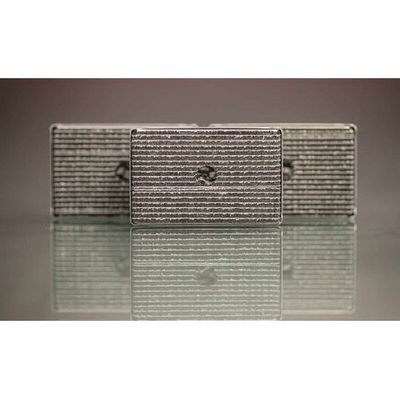

KULR - Model PCM -Phase Change Materials

A carbon fiber infused heat sink utilizing phase change materials (PCM) to absorb or provide heat. It successfully reduces system temperature excursions and extends both the life of key components in your product as well as overall operating times. Due to its low mass, it saves on weight and volume by reducing or even eliminating the need for active cooling.

An ideal solution for thermal management issues in the Aerospace and Defense industry, as it has a highly effective heat capacity over a small temperature range. This is necessary for a number of applications, including the use of batteries in space, high power lasers, and RF components. Can be particularly useful for compact and high-performance devices that require bursts of computational power in short time intervals. Additionally, we have developed a proprietary high thermal conductivity fiber core material to achieve fast and uniform melting of PCM in any orientation while in low gravity. KULR’s thermal management solution more effectively regulates such high-power conditions thus keeping devices cool.

KULR’s PCM heat sink technology is compact, reliable, and lightweight and has been utilized by leaders in the US aerospace and defense industries. It is inside NASA’s X-38 re-entry vehicle, LEO flight, Mercury Messenger satellite, and NICER telescope on the International Space Station. At current estimates the capacitor has cycled more than 10,000 times without breakage in various applications.

- PARA Charge Mass 300 MG to 14.5 kg

- Latent Heat Capacity 75 Joules to 3.6 MJ

- Melting Point Range -50°C to 76°C

- Core Conductivity As high as 230 W/m-K

- Temperature Capability -130°C to +130°C

- ARA PCM Mass Fraction As high as 70%

- ARA PCM Volume Fraction As high as 84%

- Environmental Pressure Range 1 atm to hard vacuum

- Lifetime in Space 11 years demonstrated

- Cycle Life 10,000 tested without failure;

- expectation is much longer

- Toxicity Our primary PCMs of choice are nontoxic and non-corrosive