- Home

- Companies

- Plasma Etch, Inc.

- Products

- Plasma-Etch - Model MK-II - Plasma ...

Plasma-Etch - Model MK-II -Plasma Etching System

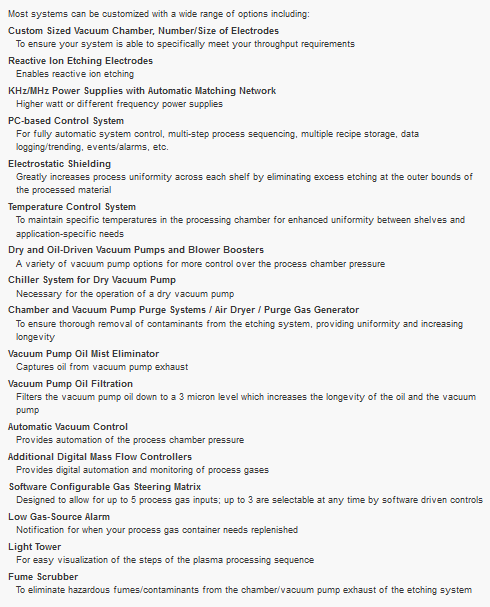

The MK-II plasma etching system offers technological advantages such as the unique combination of process temperature control and electrostatic shielding. Both work in harmony to produce the most consistent, most uniform, and most reliable etch rates obtainable across an entire board`s surface.

The MK-II is an excellent choice for use in industrial clean room settings as a plasma etching system.

This system works very well for treating flexible circuits. Flexile circuits may be placed on the horizontal shelves to prevent movement and shorting between electrodes.

Our patented gasless technology, originally developed for larger systems, is available on the MK-II and allows unmatched speed and uniformity.

The gasless MK-II is able to perform desmear and etch back without the added expense and environmental impact of CF4 gas. The system uses only electricity and oxygen.

Not only can you etch and desmear without CF4 gas, but customers have reported the gasless MK-II etching faster and more uniformly than a standard MK-II running CF4.

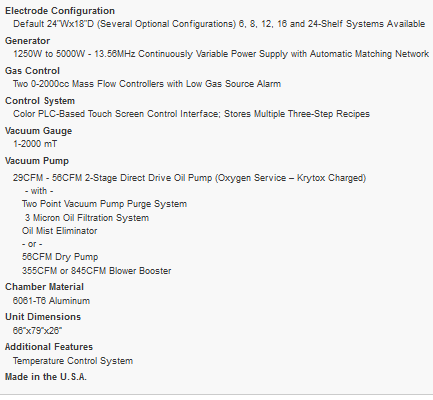

- Electrical 120/208 VAC, 50/60 Hz @ 50-100Amps, 3 Phase, 5 Wire

- Compressed Air Service 80-100PSI, 0.5CFM

- Regulated Process Gases 15-30PSI

- Cooling Cooling Water Source for RF Generator @ 2GPM