- Home

- Companies

- Dongguan Vnovo New Material Technology ...

- Products

- Vnovo - Model T - Plastic Gear Grease

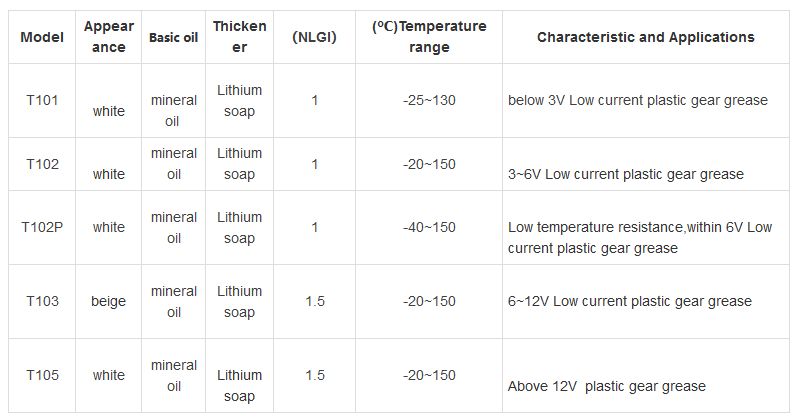

Vnovo - Model T -Plastic Gear Grease

Plastic gears are the key basic components of mechanical equipment products.Plastic and composite gears can replace non-ferrous metal or alloy gears in many cases because of their advantages of light weight, low price, low transmission noise, fewer production processes, and at the same time the strength is close to that of metal gears.and widely used in industrial manufacturing, such as auto parts, instrumentation, digital electronics, household appliances, toys, energy, transportation and aviation and other fields In order to ensure the correct lubrication of the gear parts of the equipment, it is necessary to know the operating conditions of the equipment in detail (including operating temperature, load, operating speed, structure, material, surrounding environment, etc) to facilitate the selection of the type of lubricating grease .and meet the lifetime lubrication requirements of the product.

There are several criteria to consider when choosing the plastic gear grease:

- When plastic gear grease is used for assembly type products, it is impossible to add and maintain in the middle It needs to meet the lifetime lubrication and the long life of gears.

- Good compatibility with plastics, because there are many types of plastic parts materials, it must be required that the assembly type grease must not have volume expansion, shrinkage, cracking, and mechanical properties decline with the plastic parts;

- Suitable viscosity. Strong adhesion, thick oil film, can reduce noise and improve comfort.

- Can meet the high low temperature requirements of the product, the starting and running torque is small and it has no effect on the current.

Low-odor, light-colored grease prevents pollution and meets EU environmental requirements.