- Home

- Companies

- Falcon Autotech Pvt Ltd

- Products

- Falcon Autotech - Pop-Up Sorter System

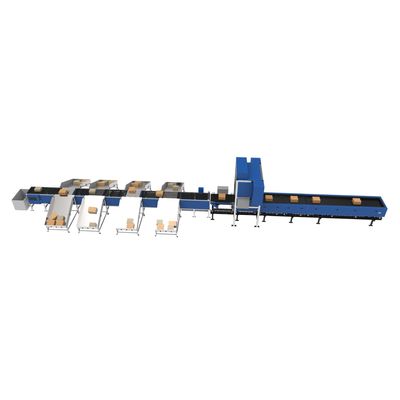

Falcon Autotech - Pop-Up Sorter System

Pop-Up Sorter System developed by Falcon Autotech is an extremely cost effective Sortation System designed for low to medium volume centres. Pop-Up Sorter can be configured to yield throughput of up to 1500 sorts per hour and is based on a highly modular design to scale up seamlessly with your growing needs.

Min Product Size Sortable (mm): 300x300x50

Max product Size Sortable (mm): 800x800x500

Throughput (Sorts/Hour): 1500

Max Product Weight Sortable (kg): 50kg

- Extremely Gentle Product Handling

- Fits is Tight Spaces

- Offers 90 Degree Divert: Narrow Chute Width

- Quick ROI and Lower Maintenance

- Highly robust and offers maximum Uptime

- Low manufacturing and Deployment lead time

Extremely Gentle Handling

Product handling is very smooth and suitable for any fragile goods.

Narrow Chutes

90 degree diverts with narrow chutes enable high space saving.

Modular Design

Modular design and placement of pop up units depending upon the site requirement.

LAUNCH PAD

Operators can drop the bulk parcels on the loading conveyor that slowly pushes the parcels on the orientation conveyor.

DWS SYSTEM

Falcon Autotech uses most reliable dimensioning and weighing technologies from top global suppliers such as SICK, Mettler Toledo, OCS, etc. Capable of providing dimensioning accuracy of +-5mm and weighing accuracy of +-50 gm at high speed.

INFEED AND OUTFEED CONVEYORS

Wide variety of powered roller and belt conveyors for moving the shipments to and fro from the docks for complete automation experience.

TAKE AWAY CONVEYORS

Conveyors designed near the end chutes to carry the sorted shipment bags/crates/totes out from the sorting area and freeing the operators to continue their tasks.