- Home

- Companies

- Del Mar Avionics, Inc

- Products

- Hydra Set - Precision Load Positioning ...

Hydra Set - Precision Load Positioning System

Since 1965, the Hydra Set Load Positioning System has been the gold standard for the precise vertical control of heavy loads over a wide variety of applications and industries.

The main advantages of the Hydra Set over alternative methods include:

- Elimination of damage to expensive loads and support fixtures

- Creation of a safer work environment

- Improvement of productivity through decreased labor costs

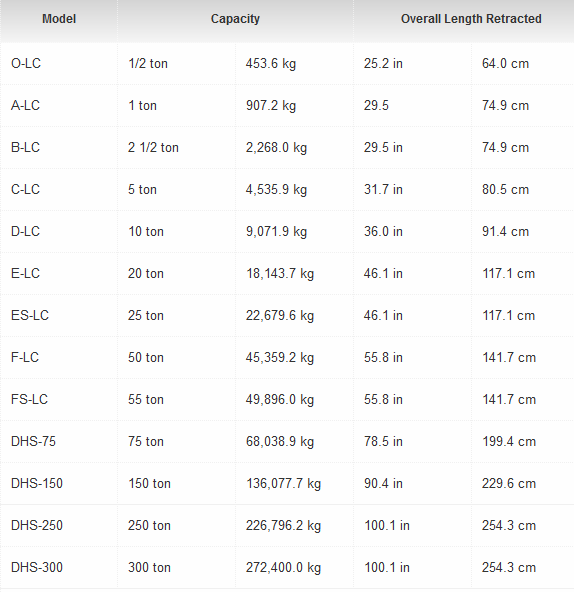

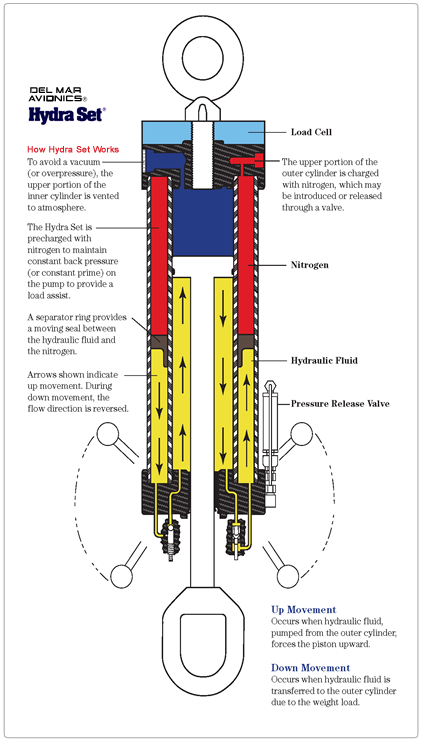

Choose from 13 standard models with capacities from ½ (453.6 kg) ton to 300 tons (272,000 kg) and from four methods of operation: manual, pneumatic, electro-hydraulic and wireless. Your crew can safely and efficiently operate the Hydra Set to precisely position loads in vertical increments of 0.001-inch (0.025mm).

Standard models (O through D) are furnished with an eye-type upper connector and a \\`D\\`-shaped lower connector. Standard models E, ES, F and FS are furnished with \\`D\\`-shaped upper/lower connectors. Standard DHS models (75 through 300-ton) are furnished with shackle-type connector and safety hook lower connector.

Please note: Hydra Set Precision Load Positioners are available with special eyes, hooks, connectors, longer or shorter stroke lengths and other variables. Ask us about special requirements.

More than 3,000 Hydra Set Load Positioners are utilized in a wide variety of industries and applications, including rugged environments worldwide.

- AEROSPACE: Satellite assembly, positioning and testing

- COMMERCIAL AVIATION; Component assembly and load testing; landing gear and horizontal/vertical stabilizer assembly; engine installation and removal

- NUCLEAR AND FOSSILE FUEL POWER GENERATING PLANTS: Construction; fuel rod replacement; transformer placement; turbine teardown, rebuild and bearing changes

- HEAVY INDUSTRY: Mill roll changes; bearing inspection; tool and mold changes, machinery loading